Foam Compactor & Densifier

Efficient & Eco-Friendly EPS Foam Compactors for Sustainable Waste Management

EPS Foam Compactors are specialized machines designed to compress Expanded Polystyrene (EPS) waste—commonly known as Styrofoam—into dense, manageable blocks. By reducing the volume of EPS by up to 90–95%, these compactors minimize landfill usage, lower transportation costs, and prepare the material for recycling into new products.

Given EPS's lightweight yet bulky nature, traditional waste handling is inefficient. Our efficient and eco-friendly EPS compactors offer a sustainable solution, helping businesses and municipalities achieve green waste management goals and promote a circular economy.

Why Choose an EPS Foam Compactor?

Volume Reduction: Compresses loose EPS into high-density blocks, making storage and logistics far more economical.

Recyclability: Turns waste EPS into a valuable raw material for manufacturing new plastic products, such as picture frames, construction materials, or decorative moldings.

Eco-Friendly: Reduces landfill waste and carbon footprint associated with EPS disposal.

Cost Saving: Cuts down significantly on waste hauling and landfill fees.

-

01

The FHML400B eps hot melting line adopt the conveyer belt, air blower and silo system to increase th

Polystyrene Foam Melting Production Line

The FHML400B eps hot melting line adopt the conveyer belt, air blower and silo system to increase th

View Details> -

02

The FHM100C mini EPS hot melt machine is often used in the supermarket, seafood market, hotels and

Mini EPS Styrofoam Densifier

The FHM100C mini EPS hot melt machine is often used in the supermarket, seafood market, hotels and

View Details> -

03

This EPS hot melting recycling machine includes belt conveyor before crushing and melting instead of

EPS Hot Melting Recycling Machine With Belt Conveyor

This EPS hot melting recycling machine includes belt conveyor before crushing and melting instead of

View Details> -

04

This design purpose of Foam Hot Melting Machine is to solve the problem of volume reduction of dry f

EPE EPP XPS Foam Hot Melting Machine

This design purpose of Foam Hot Melting Machine is to solve the problem of volume reduction of dry f

View Details> -

05

Most polystyrene foam products are currently not recycled due to the lack of incentive to invest in

Foam Hydraulic Compactor

Most polystyrene foam products are currently not recycled due to the lack of incentive to invest in

View Details> -

06

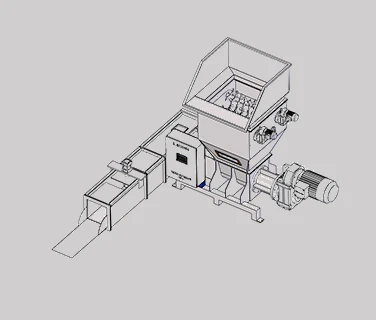

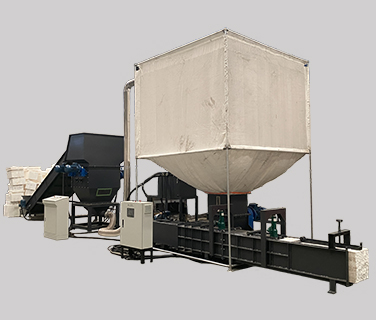

Big capacity styrofoam hydraulic compacting Production line is a machine to reduce the size of expan

Foam Hydraulic Compactor with Silo System

Big capacity styrofoam hydraulic compacting Production line is a machine to reduce the size of expan

View Details>

Why Our EPS Foam Compactors Stand Out

Customized solutions based on waste volume and site needs

Available in multiple capacities (100 kg/h to 300 kg/h and beyond)

CE-certified, compliant with international safety and environmental standards

Strong after-sales service and technical support

ADVANTAGES

-

01

Selected Siemens, Schneider, Omron, Delta, ABB, etc international brands, ensures safe and reliable machine operation with a long service life.

-

02

Machine has excellent performance, low noise, easily and convenient operation and maintenance.

-

03

The machine has CE certification and RoHS certification.

-

04

Reasonable customized equipment, designed interaction operation panel.

FAQ

-

How To Ensures Quality?

+(1) In order to ensure the accuracy of each part, we are equipped with various professional processing equipment, and we have accumulated professional processing methods in the past few years.

(2) Each component before assembly needs to be strictly controlled by inspectors.

(3) After all equipment is completed, we will connect all machines and run the entire production line before delivery. You are welcomed to ask authority agency to visit our factory and inspect machine.

-

Your Company Is A Trading Company Or A Direct Factory?

+We are a direct factory located in Zhangjiagang City. Very close to Shanghai and Wuxi (airport and train provided). If you arrive in Shanghai or Wuxi, we can pick you up to visit our factory.

-

You Are Welcome To Our Factory At Any Time

+If we can full fill your request and you interested in our products, you may pay a visit to Famous Machine site.

The meaning of visiting supplier, because seeing is believing, Famous Machinery has own manufacture and technical team, we can send you engineers and make sure your after sales service.

-

How To Guarantee Your Funds To Be Safe And Delivery To Be On Time?

+By letter of credit, you can lock the delivery time easily.

After the factory visit, You can ensure the facticity of our bank account.

Through Alibaba trade assurance service, it will ensure the on time delivery and the quality of the equipment you want to buy.

-

If We Buy Your Machine, What Is Your Guarantee Or Guarantee Of Quality?

+We provide you with high-quality machines with 1-year warranty and lifetime technical support.