EPS Foam Screw Compactor

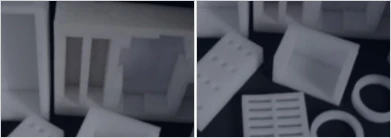

EPS foam screw compactor is the machine for compacting EPS foams. The FCP380 polystyrene compactor can compact the EPS at a ratio of up to 50:1. The density of the compacted blocks is approx. 350 kg/m³. The compacted block size is about 380*380mm.

- Product Description

- Applicable Materials

- Product Features

- Specifications

- Machine Video

PRODUCT DESCRIPTION

EPS foam screw compactor is specially used for EPS plastic foam, polystyrene foam, such as foam box, EPS foam board, EPS foam snack box, etc. It is applicable to foam recycling enterprises, electronic factories, packaging material factories, logistics storage and transportation companies, waste recycling stations, plastic recycling enterprises, urban communities and other places. EPS foam compactor is used to reduce the volume of EPS (expanded polystyrene foam) and reduce transportation costs, also known as EPS/foam volume reducer, briquetting machine, compactor, etc. It solved the problem of large recycling volume and high transportation cost faced by the EPS recycling industry in the past, it reduced costs, and improved economic benefits.

APPLICABLE MATERIALS

-

POLYSTYRENE

EPS/ EPS DUST

EPS CUPS&TRAYS/ XPS

-

POLYETHYLENE

EPE

EPE ROLL/ EPE SHEET

-

POLYPROPYLENE

EPP

PRODUCT FEATURES

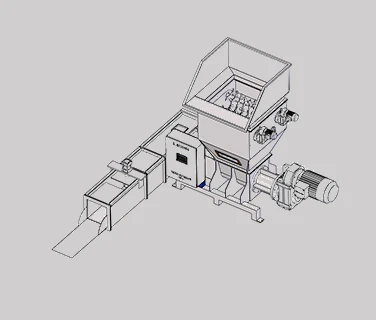

The EPS foam is pre-crushed in the hopper and extruded by the screw, the automatic hydraulic compact the EPS foams to solid and uniform blocks.

1. Low power, more capacity.

2. Turn waste to reusable material.

3. No heating in the process.

4. Can equipped with belt conveyor to reduce the manual labor.

5. Safe and easy operation with automatic PLC control.

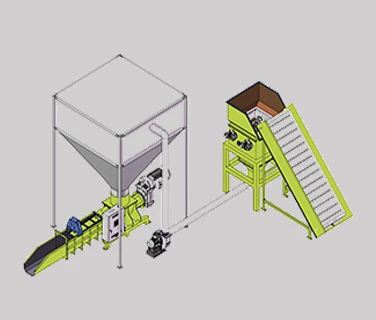

6. It can be equipped with a silo system before compacting, and the crusher part can be designed according to different materials.

SPECIFICATIONS

Model | FCP200A or FCP200B | FCP250 | FCP380 |

Screw Diameter | Φ180mm | Φ240mm | Φ350mm |

Input size | 560mmx400mm | 900mmx600mm | 1000mmx900mm |

Screw rotation speed | 36rpm | 42rpm | 42rpm |

Crusher blades | about 9sets | about 18sets | about 36sets |

Blade rotation speed | 120rpm | 120rpm | 120rpm |

Main motor | 4kw | 7.5kw | 15kw |

Crusher motor | 3kw | 3kw*2sets | 3kw*4sets |

Hydraulic motor | No | 1.5kw | 1.5kw |

Production size | 200x200mm | 250x250mm | 380*380mm |

Machine Weight | 1200kg | 1500kg | 2500kg |