Mini EPS Styrofoam Densifier

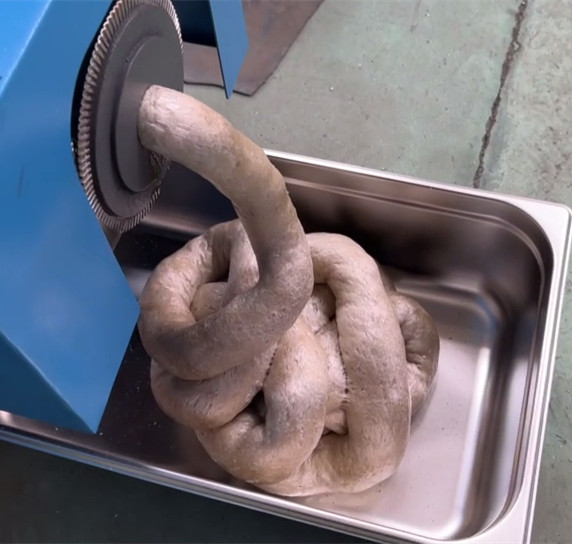

The FHM100C mini EPS hot melting machine is often used in the supermarket, seafood market, hotels and so on, processing multiple materials packing box, containers, foam box. The space of the foam materials can be reduced 80%-90%.

The crushing blades in the EPS hot melting machine can break the EPS material into small pieces and go through the screen.

The material will be fed by the extruder screw to the heating barrel. The screw of the main machine can push and heat the material to melting condition, then extrude them for easy storage and transportation.

- Product Description

- Applicable Materials

- Product Features

- Specifications

- Machine Video

PRODUCT DESCRIPTION

Our EPS hot melting recycling machine adopts manual feeding, the material will be crushed by the rotating blades and conveyed to the barrel of the main machine through the screen. This screw of the main machine can convey and heat the material to melting condition, then extrude them to pieces for easy storage and transportation.

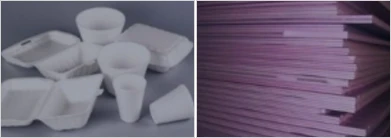

APPLICABLE MATERIALS

-

POLYSTYRENE

EPS/ EPS DUST

EPS CUPS&TRAYS/ XPS

-

POLYETHYLENE

EPE

EPE ROLL/ EPE SHEET

-

POLYPROPYLENE

EPP

PRODUCT FEATURES

1. Screw heating melting compression technology, max compression ration can reach 90:1.

2. Screw barrel each heating zones be controlled independently, more precise temperature controlling, ensure better quality EPS blocks.

3. Reasonable designed operation panel, makes the operation be easy and convenient.

4. All parts are Omron, Schneider, etc international brands, quality reliable & durable.

5. Adopting removable blades which can be separately removed and sharpened after getting blunt.

6. Suitable for smashing all kinds of soft, hard and foamed plastics.

7. Easy to operate and could be movable type.

Working Principle:

The operator firstly runs the heating system to pre-heat the screw to reach rated temperature, and then throws plastic waste into hopper of the machine, and then the pre-breaker with single rotating knife shafts will crush it into 10~50mm pieces, which are forced by a screw into the extruder system.

Suitable Products: It is suitable for EPP EPE XPS PUR EVA EPS plastic foam and polystyrene foam, such as foam box, EPS foam board, EPS foam fast food box, etc.

SPECIFICATIONS

| Model | FHM100C |

|---|---|

| Feeding size | 460*400mm |

| Screw diameter | φ80 mm |

| Screw speed | 100 r/min |

| Heating power | about 2.7kw |

| Main Motor power | 5.5kw |

| Crusher blades quantity | 7sets |

| Machine weight | about 800kg |

| Capacity | 20-30kg/h |