Mini EPS Foam Melting Machine

The FHM100B small EPS hot melt machine is often used in the supermarket, seafood market, hotels and so on, processing multiple materials packing box, containers, foam box. The space of the foam materials can be reduced 80%-90%.

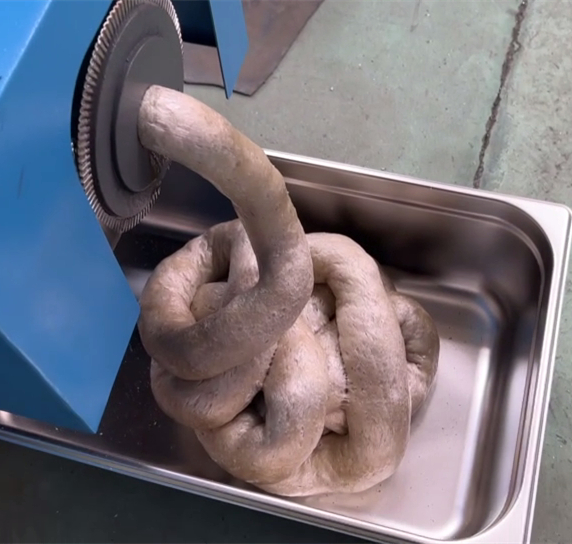

The crushing blades in the EPS hot melting machine can break the EPS material into small pieces and go through the screen.

The material will be conveyed by the high speed rotary screw to the heating barrel. The screw of the main machine can convey and heat the material to melt condition, then extrude them for easy storage and transportation.

- Product Description

- Applicable Materials

- Product Features

- Specifications

- Machine Video

PRODUCT DESCRIPTION

EPS foam hot melting is a styrofoam densifier of EPS recycling machine, which can smash the waste styrofoam materials into small pieces by the blades and screw, and then it could be easily compressed into tight foam ingots at a ratio of 90:1. After compaction, the waste foam can be reused to make other products, such as frame products and construction moldings. In addition, the applicable materials also include XPS, EPP, EPE, EPS food trays and cups. Our EPS recycling machine is able to eliminate all your waste foam recycling concerns. EPS foam hot melt densifier machine to reduce the size of expanded polystyrene foam and expanded polypropylene foam for easier transportation. It is also called EPS densifier and EPS compactor. It is widely used in sea food processing plant, electronic factories, white goods and black goods stores, and the supermarkets.

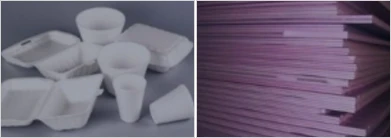

APPLICABLE MATERIALS

-

POLYSTYRENE

EPS/ EPS DUST

EPS CUPS&TRAYS/ XPS

-

POLYETHYLENE

EPE

EPE ROLL/ EPE SHEET

-

POLYPROPYLENE

EPP

PRODUCT FEATURES

1. The compression ratio could arrive at 90:1.

2. It has excellent performance, compacting dimension, low noise, easily and convenient operating and maintenance.

3. Ingenious designed feeding hopper and exquisite structure of blades.

4. With ceramic heaters on the extruder, it could make the material good plasticizing and long life working.

5. The melted material comes out from extruder, it could be collected by steel tank to get material cube block.

6. The density of the block can reach 500-600kg per cubic meter. One container can load more than 20 tons material.

7. It is suitable for EPP EPE XPS EPS plastic foam and polystyrene foam, such as foam box, EPS foam board, EPS foam fast food box, etc.

SPECIFICATIONS

| Model | FHM100A or FHM100B | FHM200 | FHM400 |

|---|---|---|---|

| Feeding size | 560*400mm | 900*600mm | 1000*900mm |

| Screw diameter | φ138 mm | φ190-120 mm | φ190-120 mm |

| Screw speed | 150 r/min | 150 r/min | 150 r/min |

| Heating power | 3kw | 10kw | 10kw |

| Main Motor power | 7.5kw | 15kw | 22kw |

| Crusher motor power | 3kw | 3kw*2sets | 3kw*4sets |

| Crusher blades quantity | about 9sets | about 18sets | about 36sets |

| Machine weight | 900kg | 1500kg | 2200kg |

| Capacity | 40-50kg/h | 80-100kg/h | 150-200kg/h |