Foam Compactor

EPS Styrofoam Compactor for Sale – Affordable Foam Recycling Solutions

Famous Machinery offers a range of EPS foam compactors, including the Small EPS Foam Compactor, Mini EPS Styrofoam Compactor, and EPS Foam Screw Compactor. Whether you need a compact, small-scale machine or a larger system with a belt conveyor and silo system, our products efficiently compress and recycle polystyrene foam, reducing space usage and improving operational efficiency. Explore the products below for more details on each model.

-

01

This Small EPS foam compactor is a mechanical and environmental protection equipment that kneads foa

Small EPS Foam Compactor

-

02

This Small EPS foam compactor is a mechanical and environmental protection equipment that kneads foa

Mini EPS Styrofoam Compactor

-

03

The equipment has a capacity of about 100kg per hour and can handle various foam wastes......

EPS Foam Compactor

-

04

EPS foam screw compactor is the machine for compacting EPS foams. The FCP380 polystyrene compactor c

EPS Foam Screw Compactor

-

05

This compactor is the machine for compacting EPS foams including the belt conveyor.

EPS Polystyrene Foam Compactor With Belt Conveyor

-

06

EPE Foam Compactor is characterized by a surface hot-melting device, especially for EPE expanded pol

EPE Foam Compactor

-

07

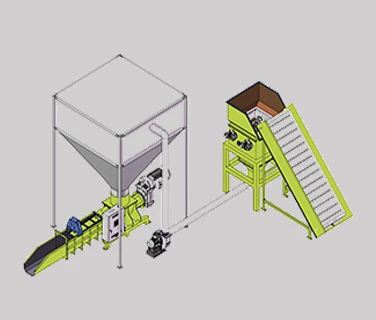

Styrofoam compacting production line is a machine to reduce the size of expanded polystyrene foam an

EPS Polystyrene Compactor With Silo System

ADVANTAGES

-

01

Our EPS foam compactors are designed to provide high-efficiency compaction, reducing the volume of EPS (Styrofoam) waste by up to 90%. This not only minimizes storage space but also significantly cuts transportation costs, making them ideal for businesses looking to streamline their waste management processes.

-

02

Whether you need a Small EPS Foam Compactor, a Mini EPS Styrofoam Compactor, or a more robust solution like the EPS Foam Screw Compactor with a belt conveyor, our range of machines offers flexibility to suit different scales of operation. From small businesses to large industrial operations, we have the right EPS compactor to meet your needs.

-

03

Built to withstand heavy-duty use, our polystyrene EPS compactors are made from high-quality materials to ensure long-lasting performance. These machines are designed for minimal maintenance and maximum durability, providing a reliable solution for your foam compaction and recycling needs.

-

04

Our EPS foam compactor price is highly competitive, providing cost-effective solutions for companies looking to reduce waste and improve their environmental footprint. By investing in our EPS polystyrene foam compactors, you not only save on waste disposal costs but also contribute to a more sustainable recycling process.

FAQ

-

How do I maintain an EPS foam compactor?

+Maintaining your EPS foam compactor involves regular cleaning and lubrication of moving parts, as well as checking for wear and tear on key components. Detailed maintenance instructions are provided with each machine, and our customer support team is always available to assist you. -

What are the advantages of using an EPS foam compactor?

+Using an EPS foam compactor offers several benefits:

Space saving: Compresses EPS foam by up to 90%, reducing storage requirements.

Cost-effective: Lowers waste disposal and transportation costs.

Environmental benefits: Helps promote foam recycling and reduces environmental impact.

Durability: Our compactors are built to last, ensuring long-term, reliable use.

-

How much does an EPS foam compactor cost?

+The EPS compactor price varies depending on the model and its features, such as the addition of a belt conveyor or silo system. For a personalized quote, please contact us with your requirements and we will provide detailed pricing based on your needs. -

Can an EPS foam compactor handle other types of foam?

+While our EPS compactors are specifically designed for polystyrene foam (Styrofoam), some models may also work with other types of foam, depending on the material's density and structure. Please contact us for advice on specific foam types. -

What types of EPS foam compactors do you offer?

+We offer a variety of EPS foam compactors to meet different needs:

Small EPS Foam Compactor for compacting smaller volumes of waste.

Mini EPS Styrofoam Compactor for compacting foam in limited spaces.

EPS Foam Screw Compactor for higher-density compaction.

EPS Polystyrene Foam Compactor with Belt Conveyor for automated foam processing.

EPS Foam Screw Compactor with Silo System for larger-scale operations.

-

How does an EPS foam compactor work?

+EPS foam compactors work by applying pressure to EPS foam waste, reducing its volume by up to 90%. The compressed foam is then typically outputted as dense blocks, making it easier to handle, store, and prepare for recycling. Some models come with additional features like belt conveyors or silo systems for automated processing. -

What is an EPS foam compactor?

+An EPS foam compactor is a machine used to compress polystyrene foam (commonly known as Styrofoam) into dense, manageable blocks. This process reduces the volume of waste, making it easier to store, transport, and recycle, contributing to a more sustainable waste management solution.