EPS Polystyrene Foam Compactor With Belt Conveyor

Most polystyrene foam products are currently not recycled due to the lack of incentive to invest in the compactors and logistical systems required. Due to the low density of polystyrene foam, it is not economical to collect. However, if the waste material goes through an initial compaction process, the material changes density from typically 30 kg/m3 to 300 kg/m3 and becomes a recyclable commodity of high value for producers of recycled plastic pellets.

- Product Description

- Applicable Materials

- Product Features

- Specifications

- Machine Video

PRODUCT DESCRIPTION

Most polystyrene foam products are currently not recycled due to the lack of incentive to invest in the compactors and logistical systems required. Due to the low density of polystyrene foam, it is not economical to collect. However, if the waste material goes through an initial compaction process, the material changes density from typically 30 kg/m3 to 300 kg/m3 and becomes a recyclable commodity of high value for producers of recycled plastic pellets.

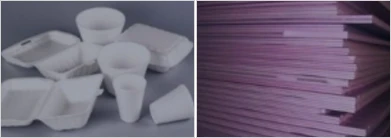

APPLICABLE MATERIALS

-

POLYSTYRENE

EPS/ EPS DUST

EPS CUPS&TRAYS/ XPS

-

POLYETHYLENE

EPE

EPE ROLL/ EPE SHEET

-

POLYPROPYLENE

EPP

PRODUCT FEATURES

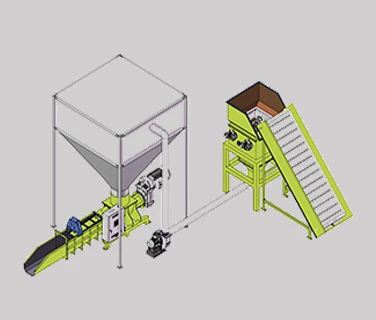

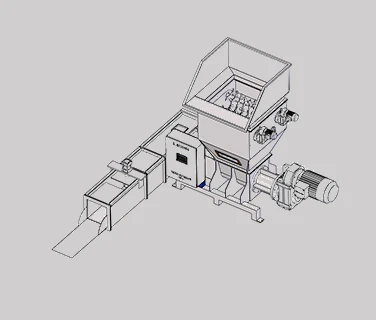

1. As an upgrade of FCP series, EPS foam compressor is equipped with belt conveyor before crushing and compression instead of manual feeding.

2. The production capacity of this series can reach 200kg/h, and the materials that can be processed are EPE expanded polyethylene, EPP expanded polypropylene, EPS expanded polystyrene, XPS extruded polystyrene, PSP polystyrene paper, food lunch boxes and cups.

3. The EPS foam can be directly crushed and extruded into blocks without heating, and the compression ratio is large, which can reduce the volume by 40-50 times and save the storage space.

4. Features of waste foam cold compactor machine: non-toxic and odorless, very green and environmentally friendly.

5. The compressed foam has a small volume, which is convenient for loading, unloading, carrying and transportation. Therefore, the FCP Series foam compactor can be transported on the vehicle, which greatly facilitates the subsequent packaging work, and constantly upgrades and optimizes the products in the application to better serve the people.

SPECIFICATIONS

Model | FCP200A or FCP200B | FCP250 | FCP380 |

Screw Diameter | Φ180mm | Φ240mm | Φ350mm |

Input size | 560mmx400mm | 900mmx600mm | 1000mmx900mm |

Screw rotation speed | 36rpm | 42rpm | 42rpm |

Crusher blades | about 9sets | about 18sets | about 36sets |

Blade rotation speed | 120rpm | 120rpm | 120rpm |

Main motor | 4kw | 7.5kw | 15kw |

Crusher motor | 3kw | 3kw*2sets | 3kw*4sets |

Hydraulic motor | No | 1.5kw | 1.5kw |

Production size | 200x200mm | 250x250mm | 380*380mm |

Machine Weight | 1200kg | 1500kg | 2500kg |