A plastic pelletizing line changes plastic waste or raw materials into small pellets. These pellets are important for recycling and making new products. It’s like giving old plastics a second chance by turning them into reusable materials. This process helps the environment and supports a growing market. For example:

1. The pelletizing machine market was worth about $2.9 billion in 2023. It is expected to grow by 3.8% each year from 2024 to 2032.

2. The plastic recycling market may grow from $27.3 billion in 2023 to $60.6 billion by 2033, with an 8.3% yearly growth rate.

These numbers show that more businesses are using plastic pelletizing lines to recycle and make products efficiently.

l Plastic pelletizing lines turn waste into reusable pellets. This helps recycling and cuts down on pollution.

l More people want pelletizing machines, showing a need for better recycling tools.

l Picking the right pelletizing system is important. Think about the material, how much you need to make, and how strong the machine is.

l Recycling plastic saves money. Manufacturers use cheaper recycled pellets and make less waste.

l Checking quality during pelletizing keeps pellet size and strength the same. This helps make better products.

A plastic pelletizing line turns plastic waste into small pellets. These pellets are easy to move, store, and reuse. The process includes melting, shaping, cooling, and cutting plastic into tiny pieces. The goal is to make good-quality pellets for recycling and manufacturing.

There are different ways to make pellets, depending on the material and needs. For example, strand pelletizing cools plastic strands in water before cutting them. Underwater hot-face cutting melts and cuts plastic in water for faster cooling. The method used depends on the type of plastic, how much is made, and the quality needed.

Component/Process | Description |

Strand Pelletizing | Plastic strands are cooled in water and cut into pellets. |

Underwater Hot-Face Cutter | Melted plastic is cut in water and dried later. |

System Components | Includes tools like cutting heads and water systems, which can be customized. |

Temperature Control | Heat must be carefully managed to keep the pellets high-quality. |

The plastic pelletizing process has several steps to ensure good results. Each step is important for turning plastic into reusable pellets.

1. Feeding the material: Plastic waste or raw materials are loaded into the machine. This can be done using belts, screws, or other tools.

2. Melting and extrusion: The plastic is heated and melted in the extruder. It is then pushed through a die head to form strands or shapes.

3. Cooling: The shaped plastic is cooled to harden it. Water baths or streams are often used for this step.

4. Cutting into pellets: The cooled plastic is cut into small, even pellets. This ensures the pellets are the same size and shape.

5. Drying and packaging: The pellets are dried to remove water and then packed for storage or shipping.

Each step is checked to ensure quality. For example, a test checks if the pellets are strong enough to handle stress. This ensures the pellets meet industry standards.

l The process includes steps like steam conditioning, cooling, and quality checks. Each step improves the final pellet quality.

l A filter is used to remove errors in data, making sure the quality checks are accurate.

Not all plastics are the same, and the type of plastic affects the process. Common plastics include polyethylene (PE) and polypropylene (PP). These plastics can melt and reform without losing their properties.

Different systems work better with certain plastics. For example:

Feature | Repro-Flex | Repro-Direct |

Main Process Materials | PE/PP Plastic film, plastic scraps, industrial plastic waste | Hard plastic wastes (pre-crushed) |

Feeding Type | Conveyor belt/ Nip-roller | Screw feeder/Conveyor belt |

Hopper | No | Yes |

Force Feeder | No | Yes (Works well with the hopper) |

Cutting Integration | Cutter compactor | None |

Some systems, like underwater pelletizers, are great for making large amounts of high-quality pellets. Strand pelletizers are cheaper and better for smaller batches. Water-ring systems are good for specific plastics and balance cost and quality.

Knowing the type of plastic and the right system helps you get better results. Whether recycling plastic film or hard plastic, choosing the right system ensures good quality and efficiency.

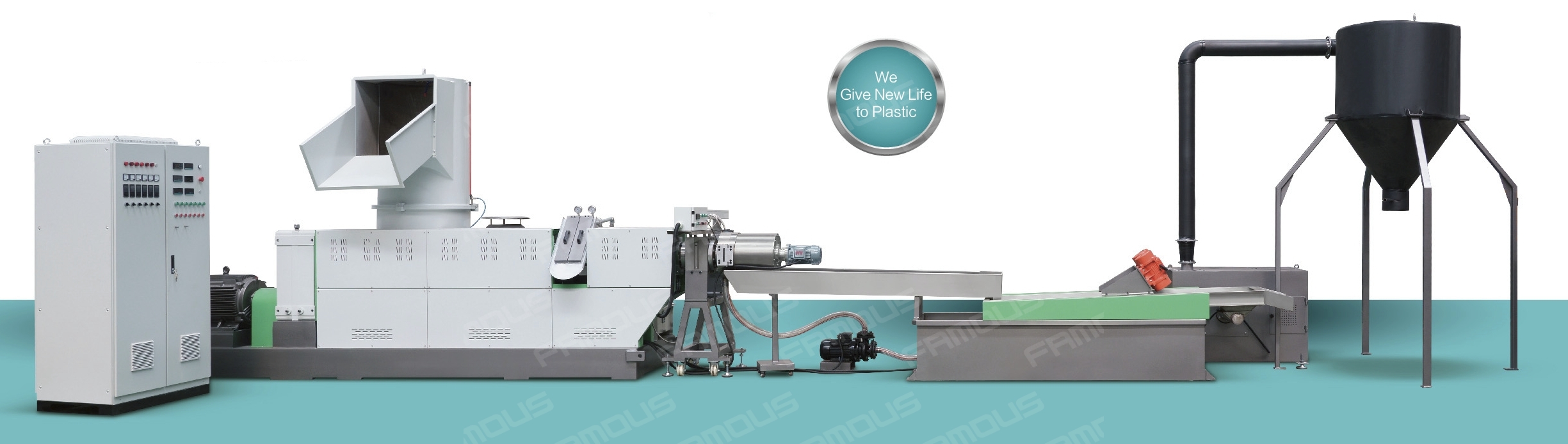

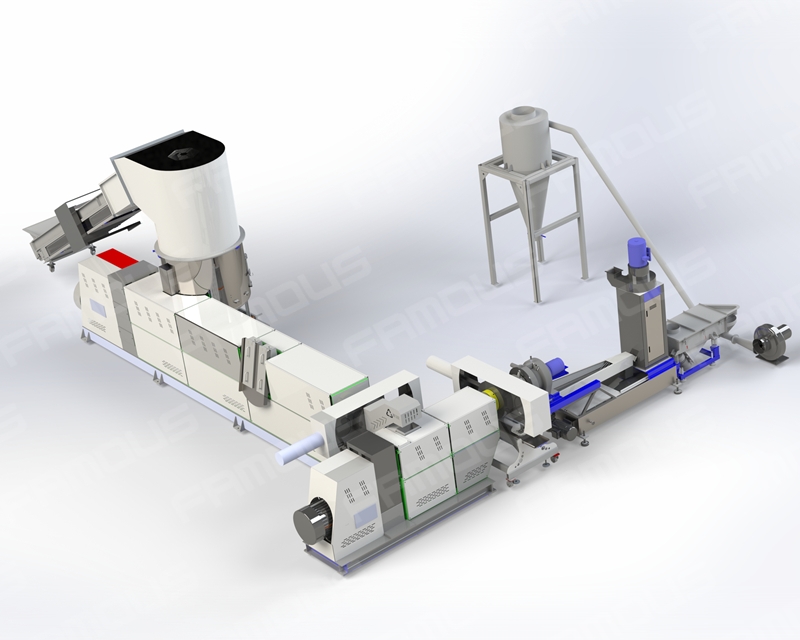

A plastic pelletizing line uses important parts to turn plastic into pellets. Each part has a job to make the process smooth and reliable.

The extruder is the main machine in the pelletizing line. It heats and mixes the plastic, getting it ready for shaping and cutting. The extruder has parts like a feeding system, barrel, screw, die head, and cooling system. These parts work together to keep the machine running well.

Specification/Parameter | Description |

Core Structure | Includes feeding system, barrel, screw, die head, cooling system, and pelletizer. |

Workflow Steps | 1. Prepare materials 2. Melt plastic 3. Shape and cut pellets |

Capacity Requirements | Small machines (100-500kg/h) for beginners; large machines (1-5 tonnes/h) for big factories. |

Screw Design | Long screws with L/D ratio over 25:1 mix better. |

Automation Degree | PLC systems control heat and warn about problems. |

The screw design matters a lot. Longer screws mix and melt plastic better. This helps the plastic get ready for the next step. Modern extruders use PLC systems to control heat and find errors. This makes the process faster and reduces mistakes.

After the extruder, the pelletizer cuts the plastic into small pellets. These pellets are easy to store and use. Different pelletizers work for different needs.

Metric | UWP Capacity | Strand Pelletizer Capacity | Water-Ring Pelletizer Capacity |

Throughput Capacity | Up to 70,000 lb/hr | Up to 44,000 lb/hr | Up to 11,000 lb/hr |

Automation | High | Moderate | Low |

Pellet Consistency | High | Moderate | Low |

Cutter Wear | Long-lasting | Standard | Standard |

l Automation: Underwater pelletizers (UWP) have advanced controls for blades and other tools.

l Versatility: Pelletizers can work with many types of plastics.

l Pellet Consistency: High-end systems make pellets that are even and flow well.

Picking the right pelletizer depends on how much you need to produce. Strand pelletizers are good for medium amounts, while water-ring systems are better for smaller batches.

Cooling and drying systems finish the pellet-making process. Cooling keeps pellets from changing shape, and drying removes water to protect the material.

Measured Outcome | Impact on Product Quality |

Ice Crystal Size | Smaller crystals cool faster but increase surface area for drying. |

Annealing Effects | Improves drying and makes the product more even. |

Primary Drying Conditions | Good temperature and pressure stop melting and damage. |

Secondary Drying Moisture Levels | Keeps moisture under 1% to avoid damage and keep quality. |

Final Product Characteristics | Pellets should be strong, stable, and meet quality rules. |

Cooling systems use water or air to harden pellets quickly. Drying systems, like dryers that spin, remove leftover water. Keeping the right temperature and pressure is key. It stops problems like melting or uneven drying, which can hurt the pellets' quality.

Tip: Using good cooling and drying systems makes your pellets stronger and more reliable.

Feeding and material handling tools are key to a plastic pelletizing line. They help move raw materials smoothly into the system. This keeps the process running without stops and ensures good-quality pellets. If feeding isn’t done right, it can cause delays or uneven pellets.

There are different feeding systems for various materials and needs. Common types include:

l Conveyor Belts: Great for light materials like plastic film or flakes.

l Screw Feeders: Work well with heavy materials like crushed hard plastics.

l Vacuum Loaders: Perfect for automated systems handling powders or granules.

These systems control how materials enter the extruder. This prevents too much or too little material from entering.

Material handling tools work with feeding systems to manage raw materials. These tools include hoppers, force feeders, and scrapers. Hoppers store materials before feeding, while scrapers clear extra material to avoid blockages.

Good handling tools reduce waste by using all the plastic efficiently. This helps make the recycling process more eco-friendly.

Several factors affect how well feeding and handling systems work. These factors ensure the pellets are consistent and high-quality. Here’s a summary:

Parameter | Description |

Feedstock physical parameters | Traits of the materials used in the process. |

Feedstock chemical composition | Chemical makeup of materials, affecting pellet quality. |

Binder and feed rates | Amounts of binder and feedstock added. |

Binder formulation and concentration | Details of the binder used, impacting pellet strength. |

Spray nozzles and locations | Placement of nozzles for applying binder. |

Feed locations | Points where materials enter the system. |

Scraper locations | Positions of scrapers for clearing materials. |

Moisture ratio | Moisture level in materials, important for pellet formation. |

Retention time | Time materials stay in the system. |

Drying parameters | Drying conditions that affect pellet quality. |

Pin arrangement | Setup of pins in the pelletizer, if used. |

Disc speed and angle | Speed and angle of the disc, affecting output. |

These factors help feeding and handling systems work well with the pelletizing line. For example, keeping the right moisture level stops clumping. Proper feed rates ensure pellets are even in size.

Tip: Check and adjust your feeding and handling tools often. This avoids problems and keeps your system working efficiently.

Using good feeding and handling tools improves the pelletizing process. It increases productivity and makes better pellets for recycling or manufacturing.

A plastic pelletizing line helps reduce plastic waste pollution. Recycling items like PET bottles keeps them out of landfills. This makes the environment cleaner and reduces harmful effects. Reusing materials also saves resources and supports recycling efforts. For instance, recycling PP and PE films cuts landfill waste. It also creates high-quality pellets that replace new plastic. This makes the process more eco-friendly and sustainable.

Recycling plastic helps protect the planet. It lowers the need to make new plastic, saving energy. This also reduces greenhouse gas emissions, helping the environment. Plastic pelletizing is an important tool for green manufacturing.

Using recycled pellets instead of raw materials saves money. Recycled pellets cost less but still work well for making products. By reusing materials, manufacturers can lower their production costs.

Pelletizing lines are efficient and reduce material waste. They produce more usable pellets from the same amount of plastic. Over time, this efficiency leads to big savings. Buying a pelletizing line can cut costs while keeping production quality high.

Plastic pelletizing lines make pellets that are the same size and quality. This is important for making products that need uniform materials. Controlling moisture and size during pelletizing improves strength. Cooling and drying make the pellets solid and reliable.

Modern pelletizing lines use automation to keep quality high. They adjust heat and pressure to meet standards. This ensures every batch of pellets is good for manufacturing. A pelletizing line helps create strong materials for better products.

Plastic pelletizing lines help recycle waste into reusable pellets. This supports the need for better waste management. Many companies now use advanced systems to recycle more efficiently. For example:

Evidence | Description |

Consumer awareness | People worry about plastic harming health and animals. |

Demand for solutions | More people want better ways to manage waste. |

Investment in technology | Companies spend money on better recycling machines. |

Modern machines use filters to remove dirt and make clean pellets. Melt filters catch impurities, and self-cleaning filters improve quality. These upgrades make recycling easier and better for the planet.

Evidence | Description |

Multi-stage filtration | Removes dirt to make high-quality pellets. |

Melt filtration | Catches impurities to keep pellets strong. |

Innovations | Self-cleaning filters improve quality and save time. |

Plastic makers save money by using pelletizing lines. Recycled pellets cost less than new materials and ensure steady supplies. Making your own pellets avoids problems like resin shortages or price hikes. Recycling also uses less energy and creates fewer emissions than making new plastic.

Benefit | Description |

Lower raw-material costs | Recycled pellets are cheaper than new plastic. |

Energy and emissions savings | Recycling uses less energy and lowers CO₂ emissions. |

Regulatory compliance | Recycling helps meet legal rules and cuts waste disposal costs. |

Supply chain stability | Making your own pellets avoids resin shortages and price jumps. |

New revenue streams | Extra pellets can be sold for profit. |

Pelletizing lines also improve product quality. Even-sized pellets make production smoother and products better. This leads to higher-quality results.

Plastic pelletizing lines can be adjusted for different industries. For example, a plant in Austria recycles 20,000 tons of plastic yearly using biomass power. It also uses AI to control moisture, saving 12% energy compared to EU standards. In Canada, a plant processes 3 tons per hour with a two-stage drying system and automated sorting, achieving 95% uptime.

Location | Capacity | Features | Energy Efficiency/Uptime |

Austria | 20,000 tons/year | Biomass-powered system, AI moisture control | 12% less energy use than EU standards |

Canada | 3 t/h | Two-stage drying, automated sorting | 95% uptime |

These examples show how custom setups improve efficiency and meet goals. Tailored systems ensure your pelletizing line fits your industry’s needs, like saving energy or boosting uptime.

Picking the right plastic pelletizing line means checking key factors. First, know your production needs, like output size and material type. If you need to process more plastic, choose a machine with high capacity.

Next, check the machine’s build and performance. Strong screws, barrels, and motors make the machine last longer. Look for systems with automation to make operations easier and faster.

Safety and quality certifications are also important. Machines that meet global standards work better and are safer. Finally, think about the total cost, including setup and maintenance. A good machine balances price and performance.

Tip: Pick a supplier with a good reputation for reliable service.

Good-quality machines make pellets that are even and smooth. This helps in making better products later. For example, pelletizer blades must cut pellets evenly for consistent results.

Durability tests check if pellets can handle shocks and wear during use. Machines meeting standards like BS EN ISO 17225-2 perform reliably. Pellet strength also depends on material type and moisture levels.

Evidence | Description |

Mechanical Durability | Tests how pellets resist shocks and wear. |

Minimum Requirements | Standards like BS EN ISO 17225-2 ensure reliability. |

Consistency in Production | Pellets should be even in size and shape. |

Strong machines reduce repairs and keep production running smoothly.

A good supplier is key to a successful plastic pelletizing line. Choose suppliers who fix problems quickly and share new ideas. They should help you improve your system’s efficiency.

Suppliers who visit regularly to check training and product quality are helpful. These visits prevent future issues and keep your machine working well. Also, pick suppliers with good after-sales support, like warranties and spare parts.

Note: A trusted supplier gives you reliable equipment and service, lowering risks in your operations.

A plastic pelletizing line changes waste into useful materials. It helps lower plastic pollution and improves manufacturing. Picking the right equipment for your needs ensures better results and lasting use.

Recycling plastic helps the planet and saves money. For example, Hartmann et al. (2019) show how it keeps waste out of landfills. However, Rahman et al. (2022) warn about microplastics. Alqahtani et al. (2021) explains it is cost-effective, while Sandanayake et al. (2020) mentions transport costs. These studies show both environmental and money-saving benefits.

Choosing the right system helps your business and the Earth. It supports sustainability and smarter use of resources.

It changes plastic waste into small, reusable pellets. These pellets help recycle plastic and make new products, reducing waste.

No, not all plastics work. Plastics like polyethylene (PE) and polypropylene (PP) are best. They melt and reshape without losing quality.

Think about your material, how much you need to make, and your budget. Choose strong machines with automation. A good supplier with support helps in the long run.

Yes, it helps by cutting down on waste and saving resources. Turning plastic into pellets reduces landfill use and the need for new materials.

Recycling centers, plastic makers, and industries needing special materials use them. These systems make work faster and create high-quality pellets for many uses.