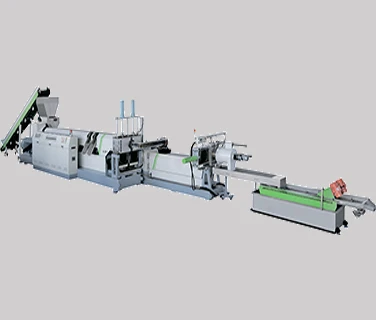

PPPE Rigid Flakes Scraps Pelletizing Line

The production line adopts European design and advanced technology. It is mainly used for clean PE PP flakes, scraps and crushed, washed, dried HDPE/LDPE/PP/PS/ABS materials. The whole line can be specially designed according to the cleanness of the customer's raw material and the quality requirement of the final product.

- Product Description

- Applicable Materials

- Product Features

- Specifications

- Machine Video

PRODUCT DESCRIPTION

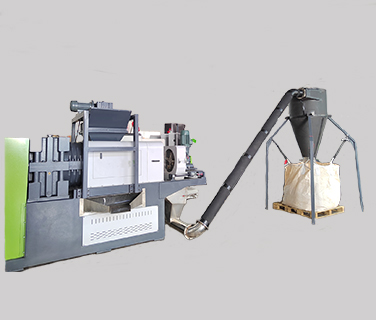

Screw loader and Dosing Feeder: Use to loading flakes into dosing feeding. Dosing feeding the material into extruder. Keep the extruder more stable working

Dosing feeder: Feeding flakes into extruder smoothly and evenly

Extruder: Made by sturdy frame, heavy. No vibrating when machine running.

1.Hydralic screen exchanger: Filtering material impurity 2.Die mould: Material come out in noodles 3.Cooling tank: Water cooling the material

Fan Dryer and pellet cutter System: The noodle pelletizing unit extrudes the strands through the single screw extruder, cools it in the water tank along the way, then dries it through the fan dryer, and finally enters the pellet cutter.

Vibration Screen: Screen out the bigger size pellet

Intelligent Control System: With CE/ROHS standard. 1. For electric control of the whole line. 2.Main electrical units: WEG, Siemens, Schneider, ABB, DELTA, Omron, RKC, etc.

APPLICABLE MATERIALS

-

RIGID PLASTICS

PRODUCT FEATURES

SPECIFICATIONS

SINGLE STAGE PELLETIZING LINE

Model | SJ100 | SJ120 | SJ150 | SJ160 | SJ180 |

main motor(kw) | 22-55 | 55-90 | 90-132 | 132-160 | 160-200 |

screw diameter(mm) | Φ100 | Φ120 | Φ150 | Φ160 | Φ180 |

screw L/D(mm) | 20-33 | 20-33 | 20-33 | 20-33 | 20-33 |

dosing screw motor power(kw) | 0.75-1.1 | 1.1-1.5 | 1.5-2.2 | 1.5-2.2 | 2.2-3 |

exhaust method | vacuum or natural exhaust | vacuum or natural exhaust | vacuum or natural exhaust | vacuum or natural exhaust | vacuum or natural exhaust |

screen changer | plate or pillar type hydraulic screen changer | plate or pillar type hydraulic screen changer | plate or pillar type hydraulic screen changer | plate or pillar type hydraulic screen changer | plate or pillar type hydraulic screen changer |

pelletizing type | water-ring or noodle pelletizer | water-ring or noodle pelletizer | water-ring or noodle pelletizer | water-ring or noodle pelletizer | water-ring or noodle pelletizer |

capacity(kg/h) | 100-200 | 200-300 | 400-500 | 500-600 | 600-800 |

TWO STAGE PELLETIZING LINE

Model | SJ100+SJ100 | SJ120+SJ120 | SJ150+SJ150 | SJ160+SJ160 | SJ180+SJ180 |

Screw diameter(mm) | Φ100+Φ100 | Φ120+Φ120 | Φ150+Φ150 | Φ160+Φ160 | Φ180+Φ180 |

mother extruder screw L/D | 20-33 | 20-33 | 20-33 | 20-33 | 20-33 |

baby extruder screw L/D | 9-12 | 9-12 | 9-12 | 9-12 | 9-12 |

mother extruder motor power(kw) | 22-55 | 55-90 | 90-132 | 132-160 | 160-200 |

baby extruder motor power(kw) | 15-22 | 22-37 | 37-45 | 45-55 | 55-75 |

exhaust method | vacuum or natural exhaust | vacuum or natural exhaust | vacuum or natural exhaust | vacuum or natural exhaust | vacuum or natural exhaust |

screen changer | plate or pillar type hydraulic screen changer | plate or pillar type hydraulic screen changer | plate or pillar type hydraulic screen changer | plate or pillar type hydraulic screen changer | plate or pillar type hydraulic screen changer |

pelletizing type | water-ring or noodle pelletizer | water-ring or noodle pelletizer | water-ring or noodle pelletizer | water-ring or noodle pelletizer | water-ring or noodle pelletizer |

capacity(kg/h) | 100-200 | 200-300 | 400-500 | 500-600 | 600-800 |