Plastic waste is a big problem for the environment. Recycling PP and PE films is especially hard. These films are thin and bendy, so they easily get dirty with oils, dirt, and labels. This makes recycling them harder. A PP/PE film washing machine helps fix this issue. It cleans the films well, making them ready to reuse.

Recycling solutions are becoming more important every year. By 2025, plastic washing machines will make up 35.3% of the recycling market. This shows how important they are for better recycling and following stricter rules. These machines also save water and chemicals, making them a smart way to handle growing plastic waste.

l PP/PE film washing machines are important for recycling plastic films. They clean these plastics so they can be reused, cutting down waste.

l These machines make recycling better by removing dirt, oil, and leftovers. This process makes clean flakes that can be used for new items.

l Using PP/PE film washing machines helps the planet. They reduce tiny plastic pollution and reuse materials to support a circular economy.

l Buying these machines saves companies money. They use less water and energy, work faster, and lower costs.

l These machines can be customized to meet different recycling needs. They handle many types of plastic films and fit into various workspaces.

Recycling PP and PE films is tricky because of their features. These films are light and bendy, which makes them easily dirty. Dirt, oils, and leftover materials stick to them. Unlike hard plastics, they are harder to collect and sort. Most recycling centers focus on hard plastics, leaving soft films unused.

Recycling these films is also hard because of technical reasons. PP and PE have similar weights, making them tough to separate. When mixed, they don’t blend well and split apart when cooled. This lowers the quality of recycled materials. Special machines, like PP/PE film washers, are needed to recycle them properly.

Throwing away PP and PE films harms the environment. These plastics often end up in landfills and break into tiny pieces over time. These tiny pieces, called microplastics, pollute the soil and water. Studies show landfills have lots of microplastics, mostly PP and PE. For example, research found PP makes up 40% of microplastics in landfill water, with about 291 particles per liter.

Breaking down these plastics also releases bad chemicals like BPA. BPA levels in landfill water can range from 1.3 to 17,200 µg/L. These chemicals hurt nature and people’s health. This shows why better recycling methods are needed to stop pollution.

Special recycling tools are important for fixing PP and PE film problems. New ideas like single-material films make recycling easier. These films replace mixed-material packaging, which is harder to recycle. Using bio-plastics and recycled materials also shows the need for advanced recycling methods.

PP/PE film washing machines are key to these solutions. They clean films well and prepare them for reuse. With these machines, industries can cut waste, recycle more, and help the planet stay healthy.

A PP/PE film washing machine cleans plastic films in steps. Each step removes dirt, oil, and residues to prepare the films for recycling. Here's how it works:

l Shredding: The machine cuts plastic films into small pieces. This makes cleaning easier in the next steps.

l High-speed washing: A fast washing system scrubs off dirt and oil. It uses underwater paddles to clean the plastic well.

l Drying: After washing, the machine dries the films using heat and machines. This step removes moisture, making the films ready for the next process.

l Automation: Smart systems control and organize each step for better results.

Different models have different speeds and power. For example, the ME-300 model cleans 300 kg/hr with 120 KW power. The ME-1000 model handles 1000 kg/hr with 270 KW power. Some machines also offer hot washing for tougher dirt, making them useful for various needs.

Model | Capacity (kg/hr) | Installed Power (KW) | Hot Washing | Water Supply (m3/hr) | Manpower (person) | Area Required (LWH) |

ME-300 | 300 | 120 | Optional | 4-5 | 2-3 | 23mx5mx3.5m |

ME-500 | 500 | 185 | Optional | 5-7 | 2-3 | 25mx6mx4.5m |

ME-1000 | 1000 | 270 | Optional | 8-10 | 4-5 | 40mx6mx5.5m |

Sorting is important for recycling. A PP/PE film washing machine uses special methods to separate clean films. These methods remove labels, glue, and other plastics. Some of the best techniques include:

Technique Used | Recovery Percentage | Reference |

Sinking-flotation with tap water | > 97% | Gundupalli et al. (2017) |

Foam flotation | > 97% | Wang et al. (2015) |

Magnetic density separation | > 94% | Serranti et al. (2015) |

Hyperspectral imaging technology (HSI) | > 96% | Bonifazi et al. (2013) |

For example, sinking-flotation uses water to separate films from heavier items. Foam flotation and magnetic separation improve sorting, reaching over 94% recovery. These methods ensure the recycled material is clean and ready to use.

Drying is the last step in recycling. It keeps the recycled flakes high-quality. Too much moisture can cause problems like hydrolysis, which lowers quality. A PP/PE film washing machine uses advanced drying to fix this.

l Moisture Control: The machine checks and adjusts moisture to avoid issues.

l Melt Flow Index: This ensures the recycled material works well in different uses.

l Near-Infrared Spectroscopy: This checks the flakes' purity for high-quality results.

Infrared drying works very well. It cuts drying time by 80%, making the process faster. Unlike older methods, it keeps the material strong, which is important for durable flakes.

1. Infrared Drying: Speeds up drying and improves efficiency.

2. Conventional Drying: Works slower and takes more time to finish.

By using these drying methods, a PP/PE film washing machine creates high-quality flakes. These flakes are ready for pelletizing or other uses.

A PP/PE film washing machine makes recycling easier. It turns dirty plastic films into clean flakes. These flakes can be reused to make new items. The machine removes tough dirt, oils, and glue. This keeps the recycled material strong and useful.

The machine shreds, washes, and dries films in one process. This saves time and uses fewer resources. It also reduces material loss during recycling. The clean flakes are ready for making new products. These products stay durable and work well.

Using this machine recovers more plastic from waste. This means less need for new plastics. It helps save natural resources and supports recycling goals.

Contamination makes recycled plastics weaker and less useful. A PP/PE film washing machine fixes this problem. Its cold washing method cleans films without using much energy. This keeps PP and PE films recyclable and strong.

l The washing process removes dirt, improving recycled PP quality.

l Cold washing works like hot washing but uses less energy.

l Recycled PP samples show better antioxidant levels, staying strong longer.

These features keep recycled plastics usable and reduce waste. More material can be reused instead of thrown away.

A PP/PE film washing machine helps keep the planet clean. Recycling plastic films stops them from polluting landfills and oceans. This lowers microplastic pollution, which harms animals and nature.

The machine uses less water and energy, making recycling greener. Clean flakes from the machine can make eco-friendly products. This supports a circular economy where materials are reused.

Investing in this machine helps businesses meet sustainability goals. It reduces waste, saves resources, and protects the Earth for the future.

PP/PE film washing machines help create a circular economy. They turn plastic waste into reusable materials, cutting down on new resources. By cleaning films, these machines make recycling easier and reduce trash. This process supports eco-friendly manufacturing and lessens waste.

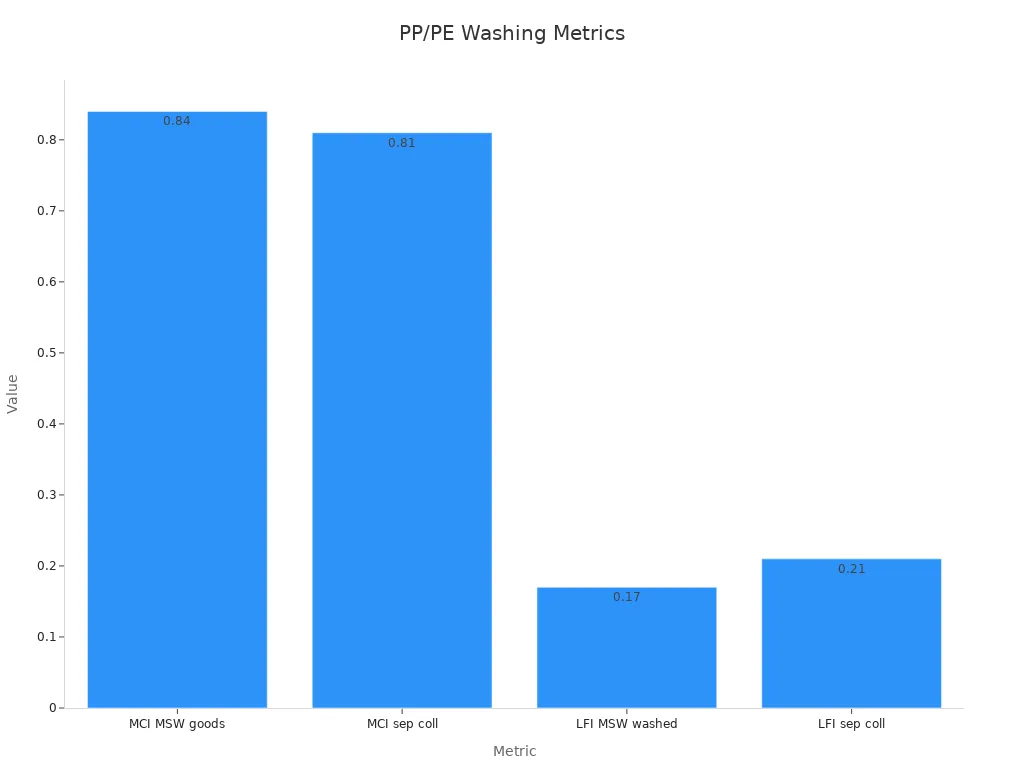

Numbers show how effective these machines are. For example, the Material Circularity Indicator (MCI) for city waste is 0.84. Separately collected items score 0.81. Sorting rigid PE packages works well at 85%, but flexible ones are harder due to mixed materials. These stats highlight the need for good washing and sorting systems.

PP/PE film washing machines save money for businesses. They use less water and energy, making them cost-effective. Automated systems speed up recycling and need fewer workers. For instance, the RUM-500 model uses 2-3 workers to clean 500 kg/h. This lowers costs and boosts productivity.

These machines also recover more usable plastic. Clean flakes from the machine are high-quality and can be reused. This reduces the need for new materials, saving money and resources.

PP/PE film washing machines can be adjusted for different tasks. Models handle 200 to 1000 kg/h, offering choices for various needs. Features like centrifugal dryers and friction washers improve cleaning. Machines can be shaped like "L" or "U" to fit your workspace.

They clean many materials, like HDPE, LDPE, and farm films. Moisture levels drop to 3%, meeting industry standards. This flexibility makes them a smart choice for better recycling operations.

Recycling PP and PE films is hard because they get dirty and are tough to sort. A PP/PE film washing machine solves this by cleaning and drying the films. It gets them ready to be used again. This machine makes recycling faster and cuts down on waste. It also helps protect the environment. Using these machines can lower plastic pollution and support reusing materials. Choosing better recycling tools helps keep the Earth clean for future generations.

These machines can clean many types of plastic films. They work with PE, LDPE, LLDPE, HDPE, PP woven bags, and jumbo bags. They are made to clean and prepare these plastics for recycling. This ensures the materials are ready to be reused as high-quality flakes.

These machines recycle plastic films by cleaning and reusing them. This reduces the amount of plastic thrown into landfills or oceans. By recycling, they help protect nature and reduce harmful pollution. This process supports a healthier planet.

Yes, these machines are built to use less energy. They have smart systems and drying methods that save power. This makes them eco-friendly and cheaper to run while still working well.

Yes, you can change these machines to fit your needs. You can pick different shapes, like "L" or "U," and add features. This helps the machine work better for your recycling tasks and space.

These machines make recycling faster and easier. They lower waste, save money, and meet eco-friendly goals. They also help companies follow environmental rules. By using these machines, industries can help keep the Earth cleaner.