PVC Profile Milling Machine/PVC Plastic Pulverizer

SMF Model high-speed plastic machine is a rotor mill, which is an ideal equipment for processing and grinding thermoplastic plastics and materials such as PVC, polystyrene PS, foamed PE, PVC, SPC and WPC. It is also an ideal processing equipment for recycling corner waste in the production of plastic products, and a good helper for plastic products enterprises to reduce costs and solve waste accumulation. This product has the characteristics of high output, low energy consumption, adjustable grinding fineness, convenient maintenance, environmental protection and pollution-free, and is well received by users, and has reached a new level compared with similar products.

- Product Description

- Applicable Materials

- Product Features

- Specifications

- Machine Video

PRODUCT DESCRIPTION

1. According to different raw materials, the output of this machine can reach 50-500kg per hour, and the mesh number can reach 10-80 meshes.

2. This product is beautiful and elegant in design, and it is a pollution-free and environment-friendly high-quality product.

3. This product has reasonable design and simple operation, and it only takes half an hour to replace the wearing parts in the machine. Compared with other similar products, it is easier to disassemble and assemble, and it is safe and reliable.

4. This product can adjust the particle thickness, and the mesh number can be adjusted to 10~80 meshes.

5. the use of water circulation and wind cooling, suitable for the processing of heat-sensitive substances.

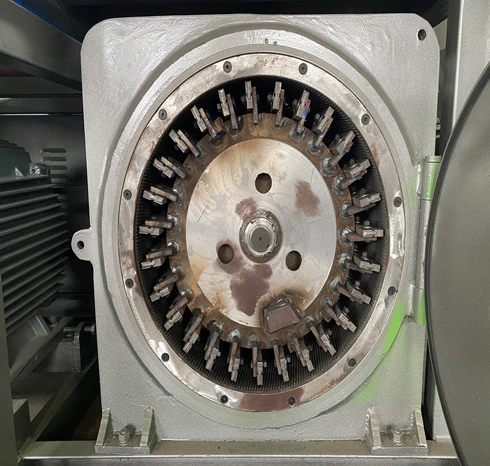

6. This machine produces high-speed rotating airflow (local vortex) due to the high-speed rotation of the spindle cutter head, which makes the incoming materials collide strongly with the blades at high speed and become powder.

7. After special design, the grinding plate and blade are all made of wear-resistant steel precision casting process, and after heat treatment, their wear resistance reaches the highest peak.

8. This machine is compact in structure and small in volume. It can be maintained as long as the door cover is opened. It is completely sealed and has no dust leakage.

APPLICABLE MATERIALS

-

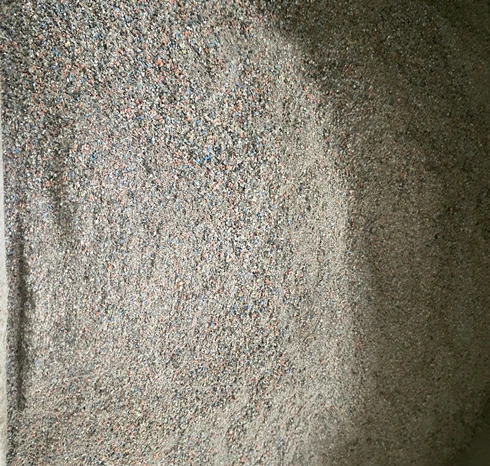

PVC FLAKES

BEFORE

AFTER

PRODUCT FEATURES

1. The capacity of this model is higher than other kind of miller.

2. Equipped with dust collection device to reduce dust pollution.

3. Close blower for discharge can reduce labor intensity of worker and save money for clients.

4.The cover of main machine can be opened for maintain.

5.The cooling system include the water and wind cooling for the machine body.

SPECIFICATIONS

Model | SMF-400 | SMF-500 | SMF-600 | SMF-800 |

Main Motor power (kw) | 30 | 37 | 45/55 | 55/75 |

Capacity (PVC 20-40 mesh) (kg/h) | 50-120 | 150-200 | 250-350 | 300-500 |

Material of conveying pipe | Stainless steel | |||

Rotary blade | 18 | 24 | 27 | 40 |

Fixed blade | 10 | 12 | 14 | 20 |

Weight of PVC pulverizer (kg) | 1000 | 1200 | 1800 | 2300 |

Cooling | Wind cooling +water cooling | |||