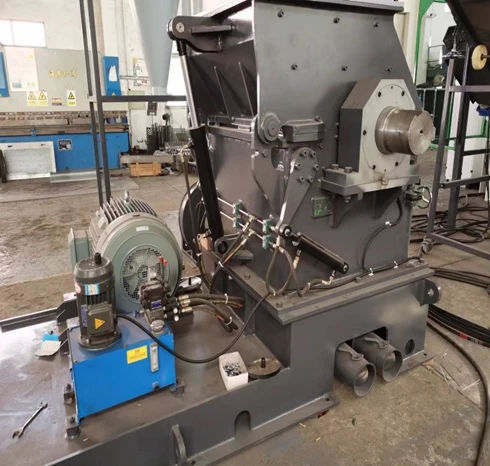

PVC Profile/PC Bottle Crusher Machine

FHC series heavy-duty crusher is widely used for direct crushing and recycling of various hollow plastic products, such as large household appliance shells, car bumpers, barrels, drums, water bottles, pvc profiles, pc bottles, oil drums, etc., and can also be used as a fine crusher after crushing block materials. The blade is made of D2 material, the highest standard in the plastic recycling machine industry.

- Product Description

- Applicable Materials

- Product Features

- Specifications

- Machine Video

PRODUCT DESCRIPTION

1.The main shaft adopts high-strength welded steel structure, with unique V-shaped design. The most suitable spindle can also be designed according to different materials. Moreover, the spindle is kept stable and reliable by strict static and dynamic leveling.

2.The upper and lower chassis and screen bracket are automatically opened and closed by hydraulic control. It is convenient to maintain the machine, remove and replace the blades and screens, and quickly complete the cleaning of the crushing box.

3.During blade changing, the spindle rotor is fixed, and the circuit is cut, so that the fixing bolts can be tightened conveniently. Do not operate the machine to protect the safety of maintenance personnel.

4.The bearing seat is installed outside the case, and wool felt is used to seal between the spindle and the case. Effectively prevent the crushed materials in the box from entering the bearing, and prolong the service life of the bearing.

5.Mesh screen size can be designed according to customer requirement and different materials.

6.Dust collection: It can separate dust and other light impurities.

7.Belt conveyor and metal detector: material feeding automatically, and can detect metal in raw materials.

8.Electric box: Main electrics use siemens or schneider, others use Chinese famous brand.

APPLICABLE MATERIALS

-

WASTE

PRODUCT FEATURES

1. Integral processing of rotor. General machine rotor parts are processed and then welded into a rotor. However, some rotors and parts will be deformed by welding, and the accuracy will be problematic. First weld the whole rotor, then process it after overall heat treatment, determine the overall accuracy, and adjust the gap between the rotor knife and the fixed knife for overall processing, so that every point can be the same.

2. Overall processing of chassis. the full-automatic CNC machining equipment of the chassis makes the machine precise.

3. Annealing the whole chassis. After welding, the steel plate of the chassis has internal tension. In order to solve this problem, the whole chassis is annealed, which makes the whole chassis stronger after long-term use.

SPECIFICATIONS

| Model | FHC600/450 | FHC800/450 | FHC800/600 | FHC1000/600 | FHC1200/600 | FHC1200/800 |

|---|---|---|---|---|---|---|

Rotor revolving diameter (mm) | 450 | 450 | 600 | 600 | 600 | 800 |

| Speed (rpm) | 580 | 580 | 520 | 520 | 520 | 480 |

| Rotating blades (pcs) | 2x3 | 2x3 | 2x5/2x7 | 2x5/2x7 | 2x5/2x7 | 2x7 |

| Fixed blades (pcs) | 2 | 4 | 4 | 4 | 4 | 4 |

| Motor power (KW) | 30 | 37 | 55 | 55/75 | 75/90 | 132 |

| Hydraulic motor (KW) | 1.1 | 1.5 | 1.5 | 1.5 | 1.5 | 3 |

| Mesh screen (mm) | 10-50 | 10-50 | 10-50 | 10-50 | 10-50 | 12-50 |

| Feeding opening size (mm) | 530x600 | 530x800 | 705x800 | 800x1000 | 850x1200 | 1200x1200 |

| Size(L*W*H) (mm) | 2000x1550x2550 | 2000x1750x3150 | 2100x1750x3200 | 2300x1950x3350 | 2300x2150x3350 | 3200x2400x4500 |

| Weight (kg) | 2600 | 3100 | 3500 | 4500 | 5500 | 9500 |

Note: The above technical parameters are only for your consideration, real technical parameters of crusher machine will be different based on crushing different material requirements, please call us for more information before purchasing.