A foam making machine lets you make foam materials. These can be polyurethane or polystyrene. You see these foams in packaging, furniture, and cars. Foam recycling means you use old foam again. You process it to make new things instead of throwing it away. Industries want better foam solutions. This is because waste is going up. Also, rules about the environment are getting tougher. The market for these machines is growing fast. This is because many people need them for packaging, building, and cars.

Aspect | Details |

Market Valuation (2024) | USD 200 million |

Forecast CAGR (2026-2033) | 8.5% |

Market Size Projection (2033) | USD 400 million |

Key Market Drivers | Environmental concerns, regulatory pressures, demand in packaging, automotive, construction |

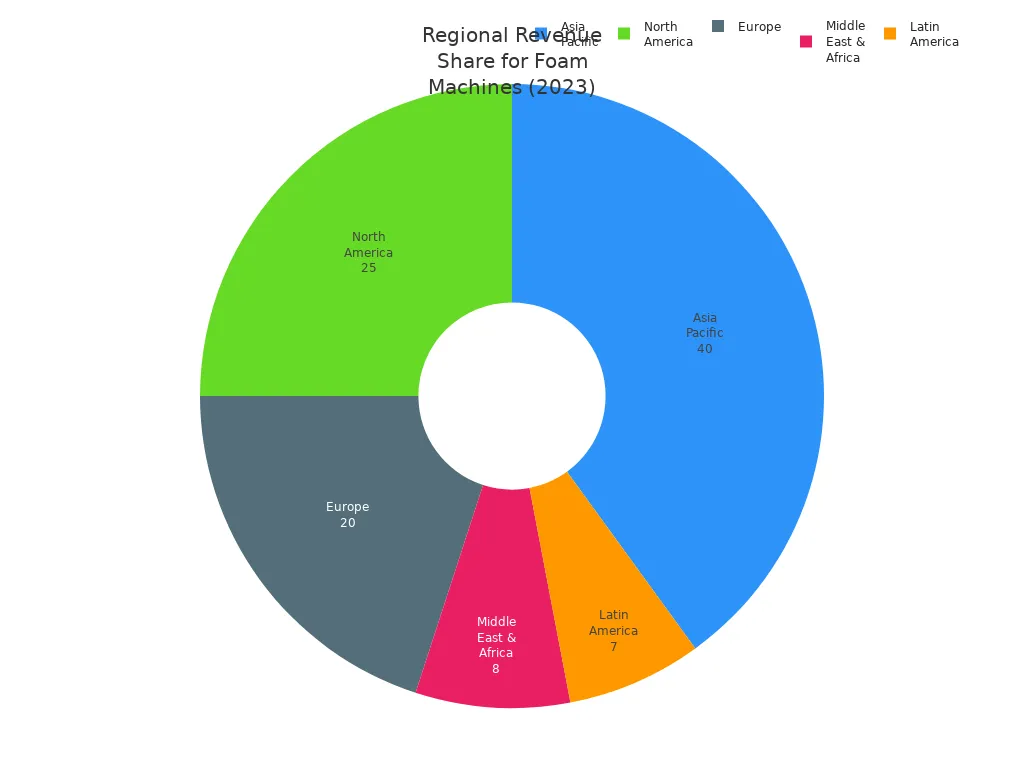

Largest & Fastest Growing Region | Asia Pacific |

You help the Earth and save money when you learn about these machines and how to recycle foam.

l Foam making machines mix chemicals and air to make foam. This foam is used in packaging, furniture, and cars.

l Recycling foam helps cut down on waste. It saves money and helps the environment by making old foam into new things.

l Mechanical recycling breaks foam into small bits. Then, it presses them into blocks. This makes it easy and saves energy to use foam again.

l Chemical recycling is best for polyurethane foam. It breaks the foam into simple parts to make new foam products.

l Advanced recycling machines shred, press, and turn foam into pellets. This helps recycle more foam and keeps the planet cleaner.

A foam making machine mixes chemicals and air to make foam. First, you put raw materials into the machine. These include polyols, isocyanates, blowing agents, surfactants, and other additives. The machine uses pumps and mixers to blend everything together.

Main components of a foam making machine:

l Foam cone

l High-flow submersible pump

l Tank for soapy water or chemical mix

l Air supply system

The pump moves the liquid from the tank to the foam cone. Inside the cone, there is a fabric membrane with tiny holes. Air blows through the membrane and makes lots of small bubbles. These bubbles stick together and form foam. The machine controls pressure and flow to keep the foam even and steady.

Tip: Always check the electrical parts and keep water away from them to stay safe during operation.

You can use these steps when working with a foam making machine: 1. Mix and measure the raw materials carefully. 2. Pump the mixture into the foam cone or mixing head. 3. Spread the mixture onto a conveyor belt with release paper. 4. Let the foam grow and harden as it moves along the belt. 5. Use pressure plates to keep the foam flat and reduce waste. 6. Let the foam dry and remove any gases. 7. Cut the foam into blocks or sheets. 8. Let the foam finish hardening in a special area. 9. Watch the whole process with computer controls for quality. 10. Collect the finished foam for use or packaging.

Safety is very important when using a foam making machine. You should wear gloves, goggles, and protective clothes. Make sure the room has good airflow. Store chemicals safely and follow all safety rules. Keep first aid kits and emergency showers close by.

A foam making machine can make many types of foam. The type depends on the raw materials and the process you use. Here are some common foams:

Foam Type | Main Uses | Recyclability and Notes |

Polyurethane Foam | Mattresses, furniture, car seats, insulation | Reusable but not recyclable. |

Polystyrene Foam (EPS) | Packaging, disposable cups, insulation panels | Commercially recyclable by melting and reforming; contains styrene, a health concern. |

Polyethylene Foam | Packaging, sports mats, protective padding | Recyclable through densification and reprocessing; most advanced recycling options. |

l Polyurethane foam is soft, strong, and lasts a long time. It is used in beds and furniture.

l Memory foam shapes to your body and eases pressure. It feels soft but can get warm.

l Gel foam has cooling gel in memory foam, so it feels cooler.

l Polystyrene foam is light and tough. You see it in packaging and insulation.

l Polyethylene foam bends easily and absorbs shocks. It keeps things safe during shipping.

The raw materials you pick change how the foam feels, how strong it is, and how long it lasts. For example, higher density foams last longer and give better support. Additives can make foam fire-resistant, stop germs, or add color.

Note: Polyethylene foam is the easiest to recycle. Polyurethane foam can be used again but not recycled. Polystyrene foam can be recycled, but only in special places.

A foam making machine lets you change the recipe and process to get the foam you want. You can make soft cushions, hard insulation, or safe packaging. This helps you meet different needs in many industries.

Mechanical recycling is the most used way to recycle foam. Machines break down foam waste and make new things from it. This process does not change the foam’s chemical structure. Instead, you cut, shred, and press the foam. This makes it easier to use again.

Here is a table that shows the main steps in mechanical foam recycling and the equipment you need for each:

Stage | Description | Required Equipment |

Collection | You collect foam waste from homes, factories, or stores. | N/A |

Sorting | You sort foam by type and quality. This helps recycle each kind the right way. | N/A |

Shredding | You cut foam into small pieces. This makes it easier to move and process. | Foam Shredders |

Densifying | You press shredded foam into tight blocks or bales. This saves space and lowers costs. | Densifiers |

Reprocessing | You melt or grind the foam to make raw material for new products. | Granulators |

End Products | You use the recycled foam to make new things, like insulation or packaging. | Complete Recycling Lines |

First, you collect and sort foam waste. Then, a foam shredder cuts the foam into small pieces. Densifiers press these pieces into blocks. This makes them easier to store and move. Granulators turn the pressed foam into small pellets or granules. These pellets can be melted and shaped into new things.

Mechanical recycling is good for the environment and saves money. You use less energy and make less waste. Many experts say this method is better for the planet than other ways. You also spend less because you do not need costly chemicals or high heat.

Tip: Mechanical recycling works best for polystyrene and polyethylene foams. You can recycle these types many times without losing quality.

Chemical recycling uses special reactions to break foam into its basic parts. You can use these parts to make new foam products. This method works well for polyurethane foam because it has a strong chemical structure.

Here are the main steps in chemical foam recycling:

1. Collect and sort foam waste.

2. Clean the foam to remove dirt and other stuff.

3. Shred or grind the foam into small pieces.

4. Press the foam to make it easier to handle.

5. Melt the pressed foam in an extruder.

6. Remove air and gases from the melted foam (degassing).

7. Filter the melted foam to get rid of impurities.

8. Turn the melted foam into pellets (pelletizing).

9. Cool and pack the pellets.

10. Send the pellets to factories.

11. Melt the pellets again and mix them with new materials.

12. Make new foam products from the recycled material.

Polyurethane foam is best for chemical recycling. You can break it down and build it into new things. Polystyrene and polyethylene foams are usually recycled by machines. You can recycle them, but chemical recycling is not as useful for these types.

Chemical recycling can help the environment. Some processes, like dissolution and depolymerization, keep the foam’s structure and use less energy. Other methods, such as pyrolysis and gasification, can also lower climate impacts if you use the outputs wisely and recover heat. But big chemical recycling plants are rare. So, the full benefits and byproducts are still being studied.

Note: Chemical recycling can lower climate change impacts by up to 40% compared to burning foam for energy.

New ways to recycle foam help you recycle more and use less energy. One of the best methods uses a twin-screw extruder. This machine lets you recycle over 75% of the foam by weight. Older methods only recycle less than 5%.

Here is a table that compares old and new foam recycling techniques:

Aspect | Traditional Methods | Advanced Technique (Twin-Screw Extruder) |

Recycling Content | Less than 5% recycled filler by weight | Over 75% recycled filler by weight |

Process Type | Energy-intensive chemical recycling | Energy-efficient mechanical recycling |

Production Scale | Limited, batch processes | Continuous industrial-scale production |

Technical Challenges | Hard to use solid recycled materials | Handles different particle sizes and materials well |

Energy Efficiency | Low | High |

Application Focus | General foam recycling | Insulation panels for green building |

Environmental Impact | High landfill waste, low recycling rates | Less waste, lower energy use |

You use several machines in advanced recycling systems. Foam shredders cut big foam blocks into small pieces, usually less than half an inch. Compactors crush, dry, and press foam scraps. They use spinning blades and heat from friction to shrink the foam and remove water. Single screw extruders melt and mix the foam at lower temperatures. Special screws and filters keep the quality high. Pelletizing machines turn the melted foam into small, even pellets. These pellets are easy to use in new products.

Modern recycling lines often have dust and water removal, metal detectors, smart controls, and self-cleaning filters. These features help you work faster, safer, and get better results. You save money on transport and get high-quality recycled foam for new uses.

Callout: Advanced recycling lets you turn more foam waste into useful products. You help the planet and support a circular economy by using these new methods.

Foam recycling starts by cutting big foam pieces into small ones. Shredders and grinders use sharp blades or rollers to chop foam into tiny granules. These machines work with EPS, polyurethane, and polyethylene foam. You can put foam in by hand or use automatic feeders. Many shredders have dust collectors to keep the area clean.

Small foam pieces are easier to store and move. They are also easier to use again. You can choose a machine size that fits your needs. Some machines handle 25 to 45 pounds each hour. Bigger machines can process up to 700 pounds per hour. The table below shows how different models work:

Model | Throughput (lbs/hr) | Feed Capacity (cu ft/hr) | Volume Reduction Ratio |

HDC-550 | 25 - 45 | 85 - 175 | 30 to 1 |

HDC-650 | 55 - 80 | 200 - 300 | 40 to 1 |

HDC-950 | 110 - 155 | 175 - 350 | 50 to 1 |

HDC-1600 | 350 - 700 | 220 - 440 | N/A |

Tip: Smaller foam pieces take up less space and cost less to move.

Compactors and densifiers make foam take up less space. Cold compactors squeeze foam into blocks without using heat. This can shrink foam by up to 98%. Thermal densifiers melt foam, making it even smaller and clean. Both machines turn loose foam into blocks or logs that are easy to carry.

l Smaller foam blocks mean fewer trash pickups and lower transport costs.

l You can sell these foam blocks for recycling and make money.

l Densifiers help you fit more foam in each truckload.

l Companies save a lot of money each year by using these machines.

Note: Compactors and densifiers keep foam out of landfills and help recycling.

Pelletizing and extrusion machines change recycled foam into new materials. First, you sort and shred the foam. Then, you compact it. Next, you melt or densify the foam and shape it into small pellets. These pellets are easy to use for making new things.

l Pellets have less than 1% water, so they are high quality.

l Pellets are all the same size and shape, which helps factories.

l Good machines use strong parts to work well for a long time.

You can use these pellets to make sneaker soles, phone cases, or gaskets. Some systems let you recycle foam right where you are. This makes recycling faster and easier. This process helps the environment and cuts down on waste.

Foam making and recycling machines help you save money. You do not have to pay as much to throw foam away. You also use less new material, so you spend less. Companies like Sterling Manufacturing show that recycling cuts waste and makes products better.

l You pay less to get rid of waste.

l You save money by using fewer new materials.

l Recycling can create jobs and new businesses.

l Good recycling programs lower costs and improve products.

l Selling recycled foam can earn extra money.

l New machines use less work, power, and other resources.

Many factories use EPS recycling machines to cut waste. These machines help them work better and save money. This proves that recycling foam is smart and helps businesses.

Recycling foam helps the planet. It keeps foam out of landfills and stops pollution. It also saves space and uses fewer new resources. When you recycle, you use less energy and make less waste. This means you help lower your carbon footprint.

Recycling foam helps companies be greener and look better to customers.

You also help cut down on greenhouse gases. New recycling methods use less energy and make less pollution than making new foam. This helps everyone have a cleaner world.

Recycled foam is used in many industries. You can find it in packaging, sports, medicine, oil and gas, safety gear, cars, electronics, building, military, shipping, pipe insulation, and furniture.

l Packaging: Use recycled foam to protect things in boxes.

l Automotive: Put recycled foam in car seats and dashboards.

l Electronics: Use foam to keep electronics safe from shocks.

l Construction: Use foam for light support and insulation.

l Medical: Use foam to protect medical tools and devices.

Some companies use foam with 20-30% recycled content. This helps products work well and be better for the environment. Starch-based and silicone foams have special features. They can absorb shocks, resist fire, and stay strong with chemicals. These benefits make recycled foam a good choice for many new products.

You have learned how a foam making machine makes helpful products. Recycling changes old foam into new things. These machines help save money and cut down on waste. They are important for many businesses. If you want to know more or get involved, you can use these resources:

l The New York State Department of Environmental Conservation gives guides and programs for better foam use.

l Local governments and companies help with Styrofoam recycling and share learning materials.

l Community events and public campaigns ask you to recycle foam and pick better packaging.

Try these tools to help the environment in a good way.