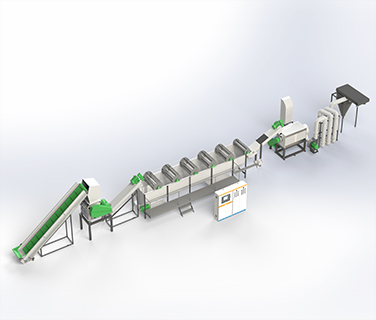

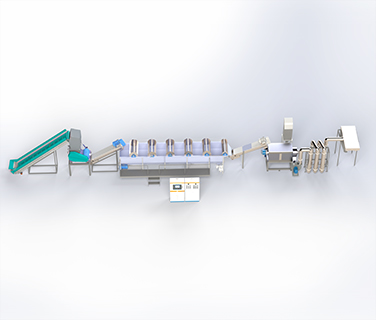

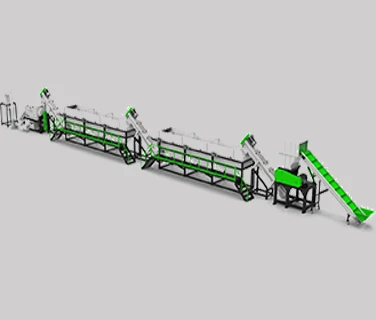

PP PE Bottle Barrel Drum Recycling Washing Line

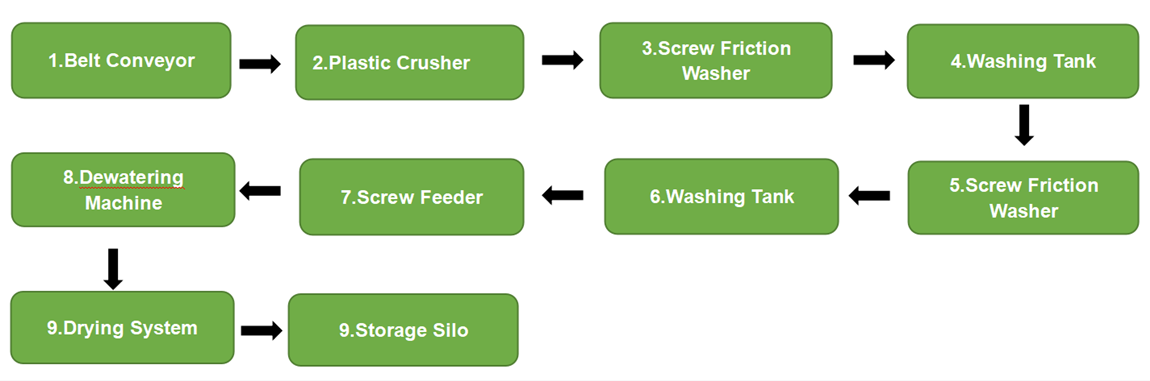

PE/PP/ABS/PS (Rigid Plastic ) Bottle, Barrel, Bucket, Hollow Container Recycling Machine It is used to recycle the waste HDPE/LDPE/PP Bottles and buckets, hollow container and so on. The production line including the conveyor belt, metal detector, plastic wet crusher, floating washing tank, high speed friction washer, centrifugal dewatering machine; drying system and label separating machine, material collecting packing system. After crushing and washing and drying, we can use it to pelletizing line. We also can customize it for you according to your requirement.

- Product Description

- Applicable Materials

- Product Features

- Specifications

- Machine Video

PRODUCT DESCRIPTION

Belt Conveyor: Conveying raw materials into next parts. 1.PVC/Rubber belt 2.Metal detector as an option 3.With inverter to adjust speed

Crusher: Function: Crushing the bottles into small pieces, wet working with water, can also choose shredder instead. 1.Crushing with water spraying in. 2.Knife adjustment outside chamber. 3.Low noise. 4.Bearings outside.

Floating Tank: Function: Washing the flakes, prevent dirty going into next process. The roller is specially made can have more washing for flakes but less water takes out. Bottom with positive and negative screw to push the dirts into middle.

Friction washer: Function: Washing out the sand, soil and dirty water from the material with high speed rotating, machine contact the material is made by SUS304.

Hot washer: Function: With hot water and chemical detergent to washing off the oil, glue and dirty(This is optional choice), machine contact the material is made by SUS304.

Dewatering Machine: Function: take out dirty and remover water. With the roller bearing and fixed outside of rotor for long use life. Inside with mesh layer, mesh diameter: 3mm

Intelligent Control System: With CE/ROHS standard. 1. For electric control of the whole line. 2. Main electrical units: WEG, Siemens, Schneider, ABB, Delta, Omron, RKC, etc.

APPLICABLE MATERIALS

-

WASTE PLASTICS

PRODUCT FEATURES

SPECIFICATIONS

| Model | Capacity | Consumption Power | Hot Washing | Water Supply | Manpower | Area Required |

| QXB-300 | 300 kg/hr | 70 kw/h | Optional | 4-5 m3/hr | 2-3 Person | 40*4*5 m |

| QXB-500 | 500 kg/hr | 140 kw/h | Optional | 6-8 m3/hr | 2-3 Person | 40*4*5 m |

| QXB-1000 | 1000 kg/hr | 280 kw/h | Optional | 8-10 m3/hr | 3-4 Person | 55*6*6 m |