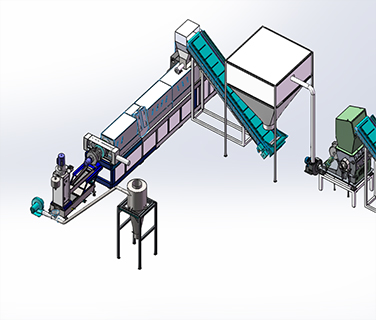

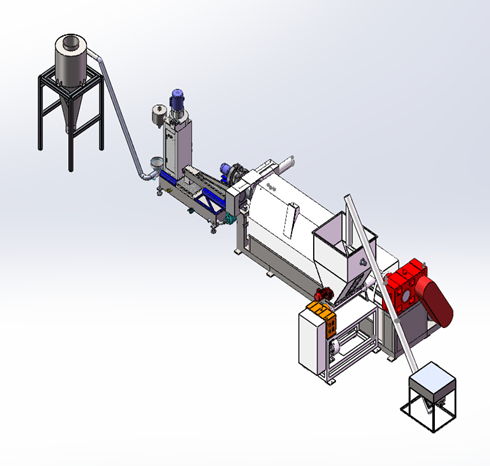

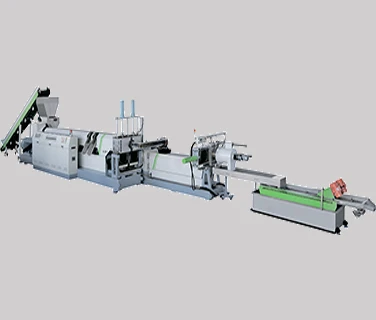

EPS Foam Water-Ring Pelletizing Line

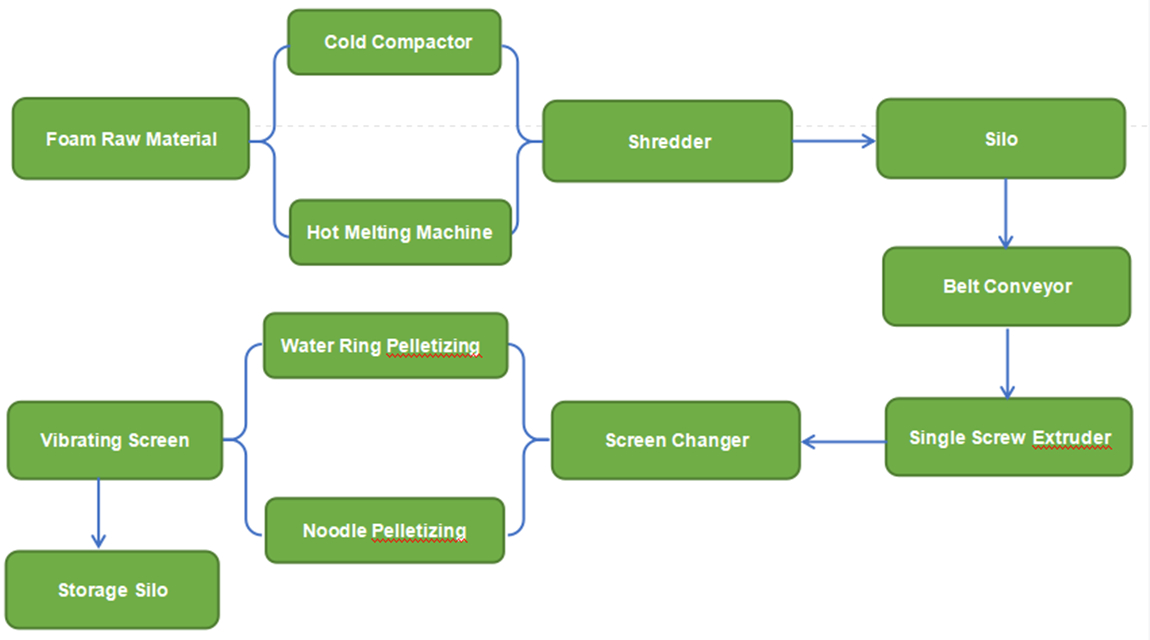

The EPS Foam Pelletizing Line is composed by shredder, belt conveyor, single screw extruder, screen changer, with water-ring pelletizing system, blower, silo and Intelligent electric control system.

Input Material: EPS EPE PS Foams, EPS EPE ingot, EPS EPE cold compressed block

Machine Capacity: 200-300kg/h(depends on different raw material density).

- Product Description

- Applicable Materials

- Product Features

- Specifications

- Machine Video

PRODUCT DESCRIPTION

EPS pelletizer machine as known as EPS foam granulator machine. EPS pelletizer machine is mainly used for the re-granulation from waste EPS expanded polystyrene, EPS foam to get PS granules to save space. One complete set includes the following parts:

1. Foam Shredder or Foam Crusher

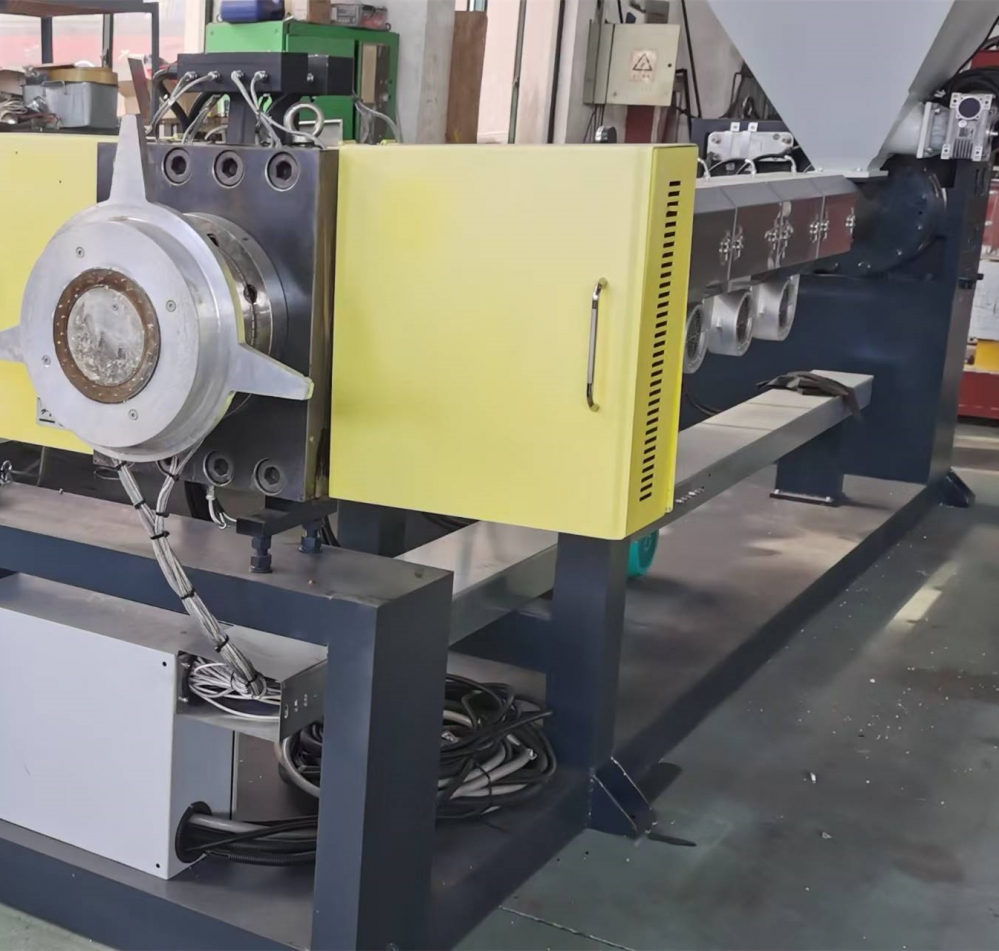

2. Main machine with single or double stage single screw extruder, hydraulic system for filter screen changer

3. Water-ring Pelletizer

4. Dewatering Machine

5. Vibrating Screen

6. Blower and Pipes

7. Storage Silo

APPLICABLE MATERIALS

-

POLYSTYRENE

EPS/ EPS DUST

EPS CUPS&TRAYS/ XPS

-

POLYETHYLENE

EPE

EPE ROLL/ EPE SHEET

-

POLYPROPYLENE

EPP

PRODUCT FEATURES

1. the compressed eps epe block will be crushed firstly, and then fed into the hopper by belt conveyor.

2. With single screw extruder, the plastic can be plasticized totally, keep the capacity steady and without air hole in the final granules.

3. With two different types of cutting way,"noodles" shape cutting and die face cutting(water-ring),we can meet your different demands for the shape of granules.

4. With Non-stop hydraulic screen changer, you can exchange the screen when the machine is running.

SPECIFICATIONS

| Machine Model | FZL-120-120 | FZL-130-130 |

| Screw Diameter (mm) | Ф120, Ф120 | Ф130, Ф130 |

| L/D (mm) | 28:1 | 28:1 |

| Main Motor Power(kw) | 90 | 110 |