A plastic film pelletizing machine changes waste plastic film into small pellets. The process starts when workers put shredded film into the machine. Inside, the material melts and goes through an extruder. The machine pushes the melted plastic through a die. It shapes the plastic and cools it. Workers collect the finished pellets. This system helps recycle plastic film waste. It turns waste into useful raw material for new products.

l Plastic film pelletizing machines help recycle waste plastic film. They melt the film and shape it into small pellets. These pellets are all the same size. Factories can use them to make new products.

l The machines work in steps. First, they feed the plastic in. Then, they melt it. Next, they push it out, cool it, and cut it into pellets. This makes sure the pellets are clean and strong. All the pellets look the same.

l The machines can handle many types of plastic films. They work with PE, PP, and multi-layer films. This makes the machines useful for many recycling jobs.

l Using pelletizing machines saves energy. It also cuts down on pollution. Factories can make recycled plastic that is high quality. This plastic works just like new material.

l The machines have automatic feeding, filtering, and cooling systems. These systems help the machines work better and faster. They also make the pellets better. This makes recycling easier and helps the environment.

A plastic film pelletizing machine helps recycling centers and factories. It changes plastic film waste into small pellets that can be used again. These machines are important in recycling. They do many jobs to make sure the plastic is clean and ready for new things.

l The machine cuts up and packs plastic film scraps.

l It melts the plastic and pushes it through a filter. This takes out dirt and other things that should not be there.

l The melted plastic goes through an extruder. This makes it into long strands.

l The strands cool off and get chopped into small, even pellets.

l The pellets dry and move to storage tanks until they are needed.

Tip: Using a plastic film pelletizing machine can save energy and work. It also helps the environment by making waste useful.

Factories use different ways to feed the machine. Hopper feeding works for soft films. Side feeding is good for steady, nonstop work. Some machines can cut, crush, melt, and pelletize all at once. This makes the job faster and easier.

Plastic film pelletizing machines can work with many kinds of plastic films. The most common ones are:

l Polyethylene (PE) films, printed or not

l Polypropylene (PP) films

l BOPP films

l Multi-layer films

l Shrink films

l Stretch films

Some machines also work with HDPE, LDPE, PVC, PLA, and even plastics that break down over time. These machines can use damaged or dirty films. They turn them into clean, even pellets. This lets recycling centers handle many types of plastic waste and help many businesses.

The pelletizing process starts with feeding. Workers or machines put shredded plastic film into the plastic film pelletizing machine. Feeding systems use belt conveyors, compactors, or force feeders. The compactor cuts and shrinks big plastic films. This makes them easier to handle. Belt conveyors move the film to the compactor. The compactor has spinning blades that cut and crush the scraps. This creates heat from friction. The heat shrinks and dries the material. The compacted film goes into the extruder quickly and evenly.

Note: Keeping feeding steady helps the machine work well. It stops overloads and underloads. These problems can cause the machine to stop or make bad pellets. Automatic feeding systems change speed based on how full the compactor is. This saves energy and makes the process better.

After feeding, the plastic film goes to the melting stage. The extruder heats the plastic until it melts. The temperature must fit the type of plastic. For example, LDPE melts at 90–125°C. HDPE melts at 125–140°C. PP melts at 130–175°C. The extruder keeps the temperature 20–30°C higher than the melting point. This makes sure the plastic melts all the way.

Plastic Type | Typical Melting Point Range (°C) |

Plasticized PVC | 75 - 90 |

Flexible PVC | 80 - 120 |

Rigid PVC | 100 - 260 |

LDPE (Low-density polyethylene) | 90 - 125 |

HDPE (High-density polyethylene) | 125 - 140 |

PP (Polypropylene) | 130 - 175 |

PET (Polyethylene terephthalate) | 225 - 260 |

PC (Polycarbonate) | 230 - 260 |

The melting process needs careful control. If the temperature is too low, the plastic will not melt right. If it is too high, the plastic can get damaged. Good melting helps the plastic flow well. It also helps make pellets with the right shape and strength. If there is water in the plastic, it can make bubbles or weak spots. Drying the plastic before melting is important.

When the plastic is melted, it goes through the extruder. The extruder has a screw and barrel. These push the melted plastic forward. This step mixes the plastic and makes it even. The extruder also takes out gases and water with a vacuum vent. The plastic then goes through a die. The die shapes the plastic into long strands.

Most plastic film pelletizing machines use single screw extruders. Some use twin screw extruders for better mixing. Twin screws are good for tricky plastics. The extrusion step is important. It makes sure the plastic is melted well and has no air bubbles or dirt.

After extrusion, the hot plastic strands must cool down. Cooling uses water baths, water rings, or air cooling. Water-ring pelletizers cool and cut the plastic at the same time. Air cooling uses a dual cyclone air chamber and a blower. This works well for plastics like TPR, EVA, and PVC that are sensitive to heat.

How fast the pellets cool changes their quality. Cooling too fast can crack the pellets. Cooling too slow can dry them out too much. The goal is to cool the pellets just enough. This makes them hard and keeps the right amount of moisture, usually not more than 10–12%. Good cooling keeps pellets strong and cuts down on waste.

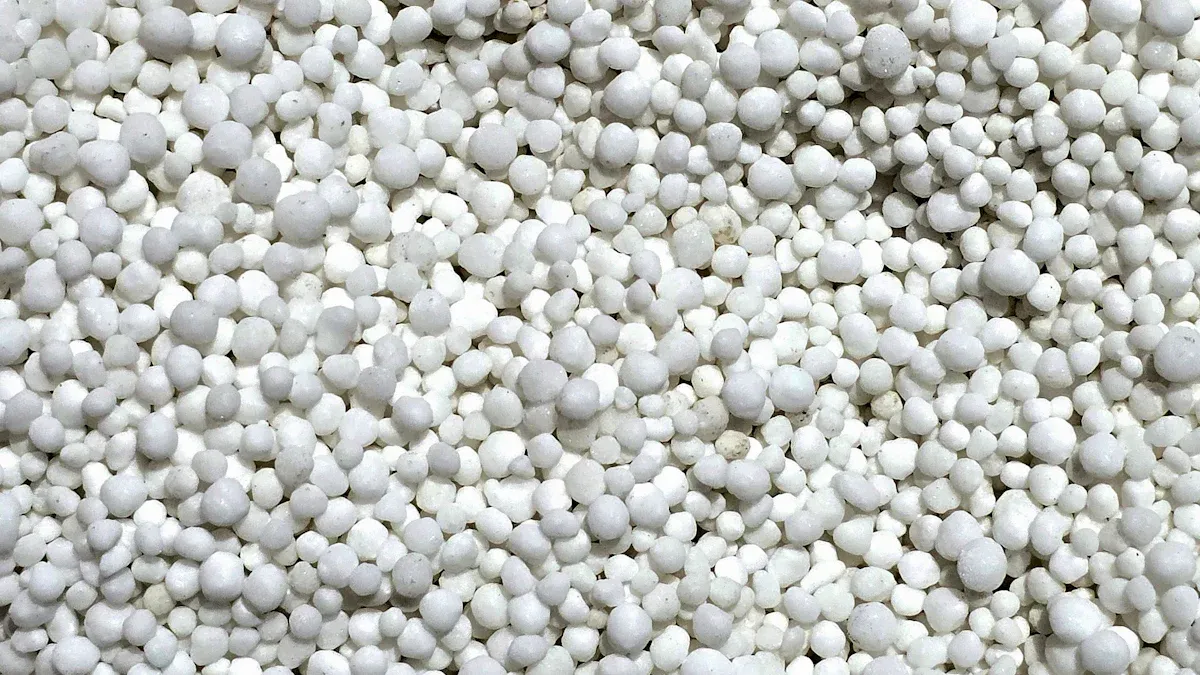

The last step is pelletizing. The cooled strands go to a pelletizer. The pelletizer cuts them into small, even pellets. Water-ring and strand pelletizers are the most common. Water-ring pelletizers cut and cool at the die face. They are good for PE and PP films. Strand pelletizers cut the strands after cooling. They make pellets that are the same size and shape.

l Water-ring pelletizers: Cut and cool at once, good for thermoplastics.

l Strand pelletizers: Cut after cooling, good for even size and shape.

Pellets need to be the same size. This helps with storage, moving, and later use. Pellets that are not the same size can cause problems in other machines. They can block machines or melt unevenly. Pellets that are all the same size make better products and less waste.

Tip: A plastic film pelletizing machine with a good pelletizer makes pellets that are easy to use in new products.

The feeding system is the first step in the machine. It has a conveyor belt that moves plastic scraps. The belt often has a metal detector. This keeps metal out and protects the machine. The compactor cuts, presses, and warms up the film. This makes the film easier to work with. It also helps the machine run better. Scientists say pellet size and shape are important. Long pellets can block pipes and slow things down. A good feeding system keeps everything steady and working well.

Component | Function/Description |

Conveyor Belt (with metal detector) | Moves scraps and checks for metal |

Compactor | Cuts, presses, and warms up the film |

The screw extruder melts and mixes the plastic film. It has a screw that turns inside a barrel. The screw pushes the plastic forward and squeezes it. This makes heat from rubbing, which melts the plastic. The screw also takes out air and water. This stops problems in the pellets. The extruder controls how the plastic melts. It sends the melted plastic to the die. This step is very important for making good pellets.

The die shapes the melted plastic into strands or other forms. The holes in the die decide how big the pellets will be. If the holes are close to the right size, the pellets come out even. The pelletizer cuts the strands into small pieces. Different pelletizers make different shapes. Water-ring pelletizers cut and cool at the same time. They make flat, round pellets. Underwater pelletizers make rounder pellets. Strand pelletizers cut solid strands into cylinder shapes. The die and pelletizer you pick change the size, shape, and quality of the pellets.

The cooling system makes the hot pellets hard after cutting. Factories use air or water to cool the pellets. Air-cooled systems save space and energy. They work well for simple film waste and make dry pellets. Water-cooled systems handle more waste and cool faster. They are good for bigger jobs and more types of film. Each system has its own good points. The choice depends on the plastic type and how much you need to process.

l Air-cooled: Saves energy, uses less space, makes dry pellets.

l Water-cooled: Handles more waste, cools fast, makes more pellets.

Screening and collection make sure only good pellets move on. Machines use screens that shake to sort out dust and broken pieces. Some systems use cameras and X-rays to check each pellet. They look for color, burns, or metal. Bad pellets get taken out by the machine. After screening, a machine or blower dries the pellets. The clean, dry pellets go into a bin or silo. They are ready to be used in new products.

Tip: Using machines for screening and collection keeps pellet quality high and cuts down on waste.

There are different pelletizing machines for different jobs. Each machine uses a special way to cut the plastic. The main ways are:

l Scissor cut type

l Helical cut type

l V-type cut model

Each cutting style shapes the pellets in its own way. Some machines stand up tall, while others lay flat. Horizontal machines are simple to use. They work best with PE films. Vertical machines are harder to use. They handle PP films and use more force for tough plastics.

Type | Operation Ease | Suitable Materials | Pressure Level | Notes |

Horizontal | Easier | PE | Lower | Good for PE, simple to use |

Vertical | More complex | PP | Higher | Handles PP, works at higher pressure |

Pelletizing machines also cool and cut plastic in different ways. Underwater pelletizers cool pellets fast in water. This lets them work all the time and make lots of pellets. Strand pelletizers cut the plastic after it cools. They can do many jobs but are slower. Hot face pelletizers make pellets the same size. They use more power and can hurt the plastic if not careful.

Pelletizer Type | Throughput & Efficiency Characteristics |

Underwater Pelletizers | High efficiency, continuous, rapid cooling, less pellet waste, higher investment needed |

Strand Pelletizers | Versatile, slower, batch process, lower cost, more maintenance |

Hot Face Pelletizers | Precise size, higher energy use, risk of polymer damage |

Note: Underwater pelletizers help factories make more pellets fast. But they cost more to buy and fix.

Recycled plastic film pellets are used in many ways. Companies use these pellets to make new things. The main uses are:

l Making bottles, trays, and tableware.

l Making wraps and films for food, medicine, and makeup.

l Making car parts that need to be light and strong.

l Making safe and clean medical tools.

l Making cases and parts for electronics.

l Making building things like window frames and insulation.

Factories recycle PE and PP films from bags and farms. Machines cut, dry, and press the waste before making pellets. These pellets can be used right away to make new things. This means less new plastic is needed.

Pelletizing machines help keep plastic in use longer. This saves energy and makes less pollution. Using recycled pellets can save up to 88% of energy. It also helps companies follow rules and gives people jobs.

Tip: Recycling plastic film pellets helps the earth and makes the future better.

Pelletizing makes recycled plastic film better in many ways. The process turns the film into pellets that are all the same size and shape. This helps factories use the pellets in new products without trouble. The recycling line can handle scraps made from different plastics but still makes even pellets. Machines with lots of automation and a small design keep the pellet quality steady.

l Recycled pellets lose very little quality, so they work well in extrusion machines.

l The process takes out water and ink by degassing, making the pellets cleaner.

l Filtration removes dirt and other things that should not be there, so the pellets are clean.

l Cooling helps the pellets keep their shape, so they are easy to move and store.

l The pellets can be used right away in film blowing, pipe making, and even for fancy film products.

Pelletizing also packs the recycled material tightly and keeps it steady. This step helps the machine feed the material better and makes the final product higher quality. Many factories say these pellets keep about 98% of the quality of new plastic. The process lets factories keep working without stopping and makes less waste.

Pelletizing plastic film waste is good for the environment. The process turns waste into pellets that can be used again, so we need less new plastic. This saves natural resources and cuts down on greenhouse gases. Factories that use pelletizing machines help keep plastic out of dumps and burning plants.

l The process lowers pollution and makes waste cheaper to handle.

l It helps save resources and makes the carbon footprint smaller.

l Companies that recycle show they care about the environment.

Recycling plastic film with pelletizing also saves energy. Good pelletizing machines can use 20–30% less energy than making new plastic. This helps the earth and saves money for factories. Recycled pellets are used in packaging, cars, and building things. This means companies spend less on new materials and help keep the planet clean.

Plastic film pelletizing machines help turn waste into useful pellets. This helps recycling and makes manufacturing better for the planet. These machines use smart controls and automation. They also have good cooling systems. This helps make pellets that are strong and all the same size.

l New pelletizing lines help cut down on pollution. They save energy and help factories spend less money.

l Automatic feeding and sorting keep the work steady. This also helps make better pellets.

l Factories can recycle many kinds of plastic. This helps save natural resources and keeps the earth cleaner.

Picking the best pelletizing technology makes work faster. It also gives better recycled materials.

Plastic film pelletizing machines can recycle many kinds of plastic film. They work with PE, PP, BOPP, shrink film, and stretch film. Some machines also handle HDPE, LDPE, PVC, and plastics that break down over time.

These machines use filters and screens to take out dirt and other things. The compactor and extruder help clean the plastic before making pellets.

Pellets that are all the same size melt the same way. They move easily in other machines. This helps factories make better products and waste less.

Recycling plastic film with pelletizing machines can save up to 88% of energy. This is compared to making new plastic. It helps factories spend less money and keeps the earth cleaner.

Many new pelletizing machines can work with different plastic films. Workers can change the settings for each type. This helps recycling centers handle many kinds of plastic waste.

Tip: Always look at the machine’s manual to find the best settings for each plastic type.

A plastic film pelletizing machine changes waste plastic film into small pellets. The process starts when workers put shredded film into the machine. Inside, the material melts and goes through an extruder. The machine pushes the melted plastic through a die. It shapes the plastic and cools it. Workers collect the finished pellets. This system helps recycle plastic film waste. It turns waste into useful raw material for new products.

l Plastic film pelletizing machines help recycle waste plastic film. They melt the film and shape it into small pellets. These pellets are all the same size. Factories can use them to make new products.

l The machines work in steps. First, they feed the plastic in. Then, they melt it. Next, they push it out, cool it, and cut it into pellets. This makes sure the pellets are clean and strong. All the pellets look the same.

l The machines can handle many types of plastic films. They work with PE, PP, and multi-layer films. This makes the machines useful for many recycling jobs.

l Using pelletizing machines saves energy. It also cuts down on pollution. Factories can make recycled plastic that is high quality. This plastic works just like new material.

l The machines have automatic feeding, filtering, and cooling systems. These systems help the machines work better and faster. They also make the pellets better. This makes recycling easier and helps the environment.

A plastic film pelletizing machine helps recycling centers and factories. It changes plastic film waste into small pellets that can be used again. These machines are important in recycling. They do many jobs to make sure the plastic is clean and ready for new things.

l The machine cuts up and packs plastic film scraps.

l It melts the plastic and pushes it through a filter. This takes out dirt and other things that should not be there.

l The melted plastic goes through an extruder. This makes it into long strands.

l The strands cool off and get chopped into small, even pellets.

l The pellets dry and move to storage tanks until they are needed.

Tip: Using a plastic film pelletizing machine can save energy and work. It also helps the environment by making waste useful.

Factories use different ways to feed the machine. Hopper feeding works for soft films. Side feeding is good for steady, nonstop work. Some machines can cut, crush, melt, and pelletize all at once. This makes the job faster and easier.

Plastic film pelletizing machines can work with many kinds of plastic films. The most common ones are:

l Polyethylene (PE) films, printed or not

l Polypropylene (PP) films

l BOPP films

l Multi-layer films

l Shrink films

l Stretch films

Some machines also work with HDPE, LDPE, PVC, PLA, and even plastics that break down over time. These machines can use damaged or dirty films. They turn them into clean, even pellets. This lets recycling centers handle many types of plastic waste and help many businesses.

The pelletizing process starts with feeding. Workers or machines put shredded plastic film into the plastic film pelletizing machine. Feeding systems use belt conveyors, compactors, or force feeders. The compactor cuts and shrinks big plastic films. This makes them easier to handle. Belt conveyors move the film to the compactor. The compactor has spinning blades that cut and crush the scraps. This creates heat from friction. The heat shrinks and dries the material. The compacted film goes into the extruder quickly and evenly.

Note: Keeping feeding steady helps the machine work well. It stops overloads and underloads. These problems can cause the machine to stop or make bad pellets. Automatic feeding systems change speed based on how full the compactor is. This saves energy and makes the process better.

After feeding, the plastic film goes to the melting stage. The extruder heats the plastic until it melts. The temperature must fit the type of plastic. For example, LDPE melts at 90–125°C. HDPE melts at 125–140°C. PP melts at 130–175°C. The extruder keeps the temperature 20–30°C higher than the melting point. This makes sure the plastic melts all the way.

Plastic Type | Typical Melting Point Range (°C) |

Plasticized PVC | 75 - 90 |

Flexible PVC | 80 - 120 |

Rigid PVC | 100 - 260 |

LDPE (Low-density polyethylene) | 90 - 125 |

HDPE (High-density polyethylene) | 125 - 140 |

PP (Polypropylene) | 130 - 175 |

PET (Polyethylene terephthalate) | 225 - 260 |

PC (Polycarbonate) | 230 - 260 |

The melting process needs careful control. If the temperature is too low, the plastic will not melt right. If it is too high, the plastic can get damaged. Good melting helps the plastic flow well. It also helps make pellets with the right shape and strength. If there is water in the plastic, it can make bubbles or weak spots. Drying the plastic before melting is important.

When the plastic is melted, it goes through the extruder. The extruder has a screw and barrel. These push the melted plastic forward. This step mixes the plastic and makes it even. The extruder also takes out gases and water with a vacuum vent. The plastic then goes through a die. The die shapes the plastic into long strands.

Most plastic film pelletizing machines use single screw extruders. Some use twin screw extruders for better mixing. Twin screws are good for tricky plastics. The extrusion step is important. It makes sure the plastic is melted well and has no air bubbles or dirt.

After extrusion, the hot plastic strands must cool down. Cooling uses water baths, water rings, or air cooling. Water-ring pelletizers cool and cut the plastic at the same time. Air cooling uses a dual cyclone air chamber and a blower. This works well for plastics like TPR, EVA, and PVC that are sensitive to heat.

How fast the pellets cool changes their quality. Cooling too fast can crack the pellets. Cooling too slow can dry them out too much. The goal is to cool the pellets just enough. This makes them hard and keeps the right amount of moisture, usually not more than 10–12%. Good cooling keeps pellets strong and cuts down on waste.

The last step is pelletizing. The cooled strands go to a pelletizer. The pelletizer cuts them into small, even pellets. Water-ring and strand pelletizers are the most common. Water-ring pelletizers cut and cool at the die face. They are good for PE and PP films. Strand pelletizers cut the strands after cooling. They make pellets that are the same size and shape.

l Water-ring pelletizers: Cut and cool at once, good for thermoplastics.

l Strand pelletizers: Cut after cooling, good for even size and shape.

Pellets need to be the same size. This helps with storage, moving, and later use. Pellets that are not the same size can cause problems in other machines. They can block machines or melt unevenly. Pellets that are all the same size make better products and less waste.

Tip: A plastic film pelletizing machine with a good pelletizer makes pellets that are easy to use in new products.

The feeding system is the first step in the machine. It has a conveyor belt that moves plastic scraps. The belt often has a metal detector. This keeps metal out and protects the machine. The compactor cuts, presses, and warms up the film. This makes the film easier to work with. It also helps the machine run better. Scientists say pellet size and shape are important. Long pellets can block pipes and slow things down. A good feeding system keeps everything steady and working well.

Component | Function/Description |

Conveyor Belt (with metal detector) | Moves scraps and checks for metal |

Compactor | Cuts, presses, and warms up the film |

The screw extruder melts and mixes the plastic film. It has a screw that turns inside a barrel. The screw pushes the plastic forward and squeezes it. This makes heat from rubbing, which melts the plastic. The screw also takes out air and water. This stops problems in the pellets. The extruder controls how the plastic melts. It sends the melted plastic to the die. This step is very important for making good pellets.

The die shapes the melted plastic into strands or other forms. The holes in the die decide how big the pellets will be. If the holes are close to the right size, the pellets come out even. The pelletizer cuts the strands into small pieces. Different pelletizers make different shapes. Water-ring pelletizers cut and cool at the same time. They make flat, round pellets. Underwater pelletizers make rounder pellets. Strand pelletizers cut solid strands into cylinder shapes. The die and pelletizer you pick change the size, shape, and quality of the pellets.

The cooling system makes the hot pellets hard after cutting. Factories use air or water to cool the pellets. Air-cooled systems save space and energy. They work well for simple film waste and make dry pellets. Water-cooled systems handle more waste and cool faster. They are good for bigger jobs and more types of film. Each system has its own good points. The choice depends on the plastic type and how much you need to process.

l Air-cooled: Saves energy, uses less space, makes dry pellets.

l Water-cooled: Handles more waste, cools fast, makes more pellets.

Screening and collection make sure only good pellets move on. Machines use screens that shake to sort out dust and broken pieces. Some systems use cameras and X-rays to check each pellet. They look for color, burns, or metal. Bad pellets get taken out by the machine. After screening, a machine or blower dries the pellets. The clean, dry pellets go into a bin or silo. They are ready to be used in new products.

Tip: Using machines for screening and collection keeps pellet quality high and cuts down on waste.

There are different pelletizing machines for different jobs. Each machine uses a special way to cut the plastic. The main ways are:

l Scissor cut type

l Helical cut type

l V-type cut model

Each cutting style shapes the pellets in its own way. Some machines stand up tall, while others lay flat. Horizontal machines are simple to use. They work best with PE films. Vertical machines are harder to use. They handle PP films and use more force for tough plastics.

Type | Operation Ease | Suitable Materials | Pressure Level | Notes |

Horizontal | Easier | PE | Lower | Good for PE, simple to use |

Vertical | More complex | PP | Higher | Handles PP, works at higher pressure |

Pelletizing machines also cool and cut plastic in different ways. Underwater pelletizers cool pellets fast in water. This lets them work all the time and make lots of pellets. Strand pelletizers cut the plastic after it cools. They can do many jobs but are slower. Hot face pelletizers make pellets the same size. They use more power and can hurt the plastic if not careful.

Pelletizer Type | Throughput & Efficiency Characteristics |

Underwater Pelletizers | High efficiency, continuous, rapid cooling, less pellet waste, higher investment needed |

Strand Pelletizers | Versatile, slower, batch process, lower cost, more maintenance |

Hot Face Pelletizers | Precise size, higher energy use, risk of polymer damage |

Note: Underwater pelletizers help factories make more pellets fast. But they cost more to buy and fix.

Recycled plastic film pellets are used in many ways. Companies use these pellets to make new things. The main uses are:

l Making bottles, trays, and tableware.

l Making wraps and films for food, medicine, and makeup.

l Making car parts that need to be light and strong.

l Making safe and clean medical tools.

l Making cases and parts for electronics.

l Making building things like window frames and insulation.

Factories recycle PE and PP films from bags and farms. Machines cut, dry, and press the waste before making pellets. These pellets can be used right away to make new things. This means less new plastic is needed.

Pelletizing machines help keep plastic in use longer. This saves energy and makes less pollution. Using recycled pellets can save up to 88% of energy. It also helps companies follow rules and gives people jobs.

Tip: Recycling plastic film pellets helps the earth and makes the future better.

Pelletizing makes recycled plastic film better in many ways. The process turns the film into pellets that are all the same size and shape. This helps factories use the pellets in new products without trouble. The recycling line can handle scraps made from different plastics but still makes even pellets. Machines with lots of automation and a small design keep the pellet quality steady.

l Recycled pellets lose very little quality, so they work well in extrusion machines.

l The process takes out water and ink by degassing, making the pellets cleaner.

l Filtration removes dirt and other things that should not be there, so the pellets are clean.

l Cooling helps the pellets keep their shape, so they are easy to move and store.

l The pellets can be used right away in film blowing, pipe making, and even for fancy film products.

Pelletizing also packs the recycled material tightly and keeps it steady. This step helps the machine feed the material better and makes the final product higher quality. Many factories say these pellets keep about 98% of the quality of new plastic. The process lets factories keep working without stopping and makes less waste.

Pelletizing plastic film waste is good for the environment. The process turns waste into pellets that can be used again, so we need less new plastic. This saves natural resources and cuts down on greenhouse gases. Factories that use pelletizing machines help keep plastic out of dumps and burning plants.

l The process lowers pollution and makes waste cheaper to handle.

l It helps save resources and makes the carbon footprint smaller.

l Companies that recycle show they care about the environment.

Recycling plastic film with pelletizing also saves energy. Good pelletizing machines can use 20–30% less energy than making new plastic. This helps the earth and saves money for factories. Recycled pellets are used in packaging, cars, and building things. This means companies spend less on new materials and help keep the planet clean.

Plastic film pelletizing machines help turn waste into useful pellets. This helps recycling and makes manufacturing better for the planet. These machines use smart controls and automation. They also have good cooling systems. This helps make pellets that are strong and all the same size.

l New pelletizing lines help cut down on pollution. They save energy and help factories spend less money.

l Automatic feeding and sorting keep the work steady. This also helps make better pellets.

l Factories can recycle many kinds of plastic. This helps save natural resources and keeps the earth cleaner.

Picking the best pelletizing technology makes work faster. It also gives better recycled materials.

Plastic film pelletizing machines can recycle many kinds of plastic film. They work with PE, PP, BOPP, shrink film, and stretch film. Some machines also handle HDPE, LDPE, PVC, and plastics that break down over time.

These machines use filters and screens to take out dirt and other things. The compactor and extruder help clean the plastic before making pellets.

Pellets that are all the same size melt the same way. They move easily in other machines. This helps factories make better products and waste less.

Recycling plastic film with pelletizing machines can save up to 88% of energy. This is compared to making new plastic. It helps factories spend less money and keeps the earth cleaner.

Many new pelletizing machines can work with different plastic films. Workers can change the settings for each type. This helps recycling centers handle many kinds of plastic waste.

Tip: Always look at the machine’s manual to find the best settings for each plastic type.