FOOD FOAM BOX SOLUTION

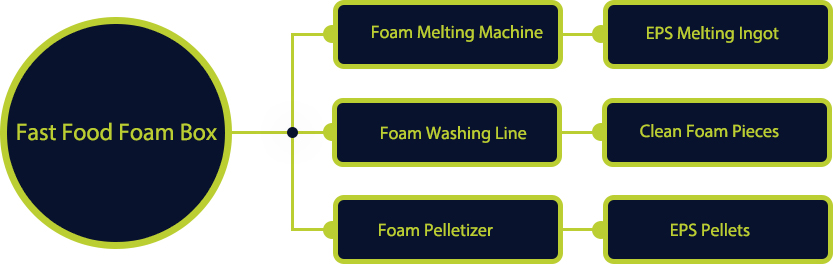

Expanded polystyrene (EPS) or foam plastic lunch boxes: These can be recycled, but practically speaking, they present significant challenges. Their light weight, bulk, high transportation costs, and susceptibility to oil and grease contamination make recycling difficult. Our company's products, including foam hot-melt machines, foam washing lines, and foam pelletizing lines, effectively recycle these containers, making them valuable.

WORK PROCESS

-

FOAM MELTING MACHINE

The foam densifier adopts screw heating melting compression technology, max compression ration can reach 90:1. After the eps foam crushing into small pieces, the foam is heated and melted in the screw through conveying and extrusion. Finally, it is extruded from the discharge port of the mold head.

-

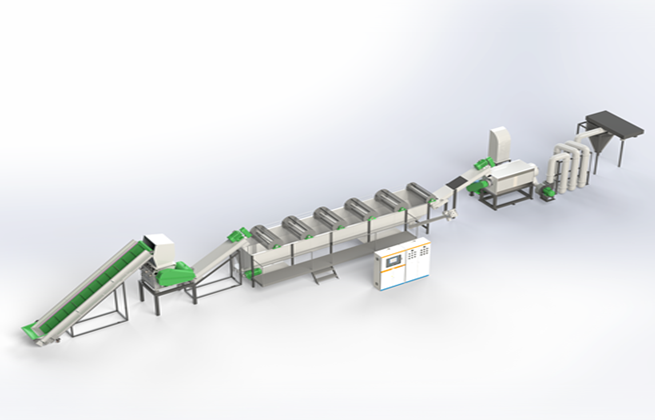

FOAM WASHING LINE

This foam recycling washing line is an EPS recycling system for contaminated EPS foam waste at first. EPS waste will be crushed into small scraps then washed and dried, finally compacted into EPS blocks.

-

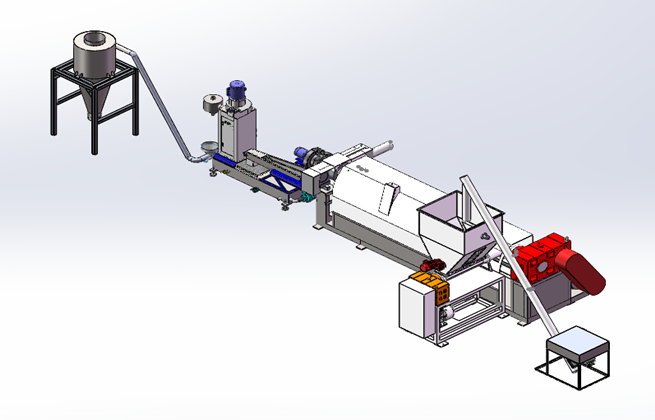

FOAM PELLETIZING LINE

The EPS Foam Pelletizing Line is composed by metering feeder, stage single screw extruder, screen changer, with spaghetti or water-ring pelletizing system, blower, silo and Intelligent electric control system.

FAQ

-

Are You A Factory Or A Trading Company?

+As a professional manufacturer, we have been in plastic recycling machine industry for more than 10 years, our factory is in Zhangjiagang city which is near shanghai and wuxi.

-

Do You Have Any Certifications?

+Yes, we have CE, RoHS Certificates.

-

What's Your Guarantee Or the Warranty Of The Quality If We Buy Your Machines?

+We offer you high quality machines with 1 year guarantee and supply life-long technical support.

-

When Can I Get My Machine After I Paid?

+Normally production time is around 30workingdays, the exactly depend on what kind of machine you order. The shipping time is based on your destination port.

-

How To Install My Machines When It Arrives? How Much The Cost?

+We will send the instruction manual and videos to you, your workers can install the machine according to it. If you still have problems in installing it and need our engineer to help, we will arrange our engineer to debugging the machine for you. At same time our engineer will give training lessons to workers in your factory. The customer need pay for visa, round air tickets, accommodation and USD100/day/person.

-

How Long Time For Installation?

+According your machines order, we will send one or two engineers to your plant, it will take about 5 days to 15 days.

-

How About The Spare Parts?

+We will send one year enough easy broken spare parts together with the machines, shipping together. During this guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If it is caused by your incorrect operations, we will provide the spare parts at cost price.