Main Machine Features And Principle

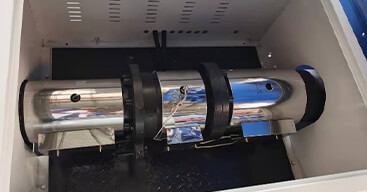

1) Screw melting technology, with the ratio of 90:1, continuously hot melting ingot material outlet, 40 high containers can carry 25 tons of high-density hot melt ingot.

2) High-quality accessories: select Siemens to ensure safe and reliable operation and long service life of the machine.

3) The machine has CE certification.

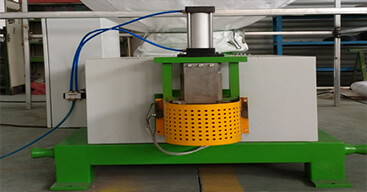

4) Three-stage temperature control to whiten the output color of hot melt as much as possible.

5) The operation is simple. No additional steps are required during operation, only start and stop operation.

6) Comply with 5S standard, foam waste is not easy to blow out and disperse to the ground during machine operation.