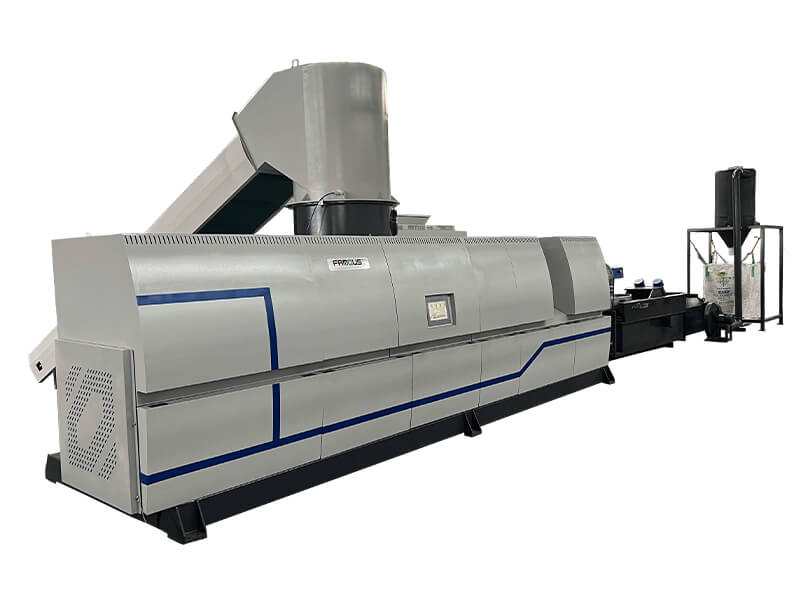

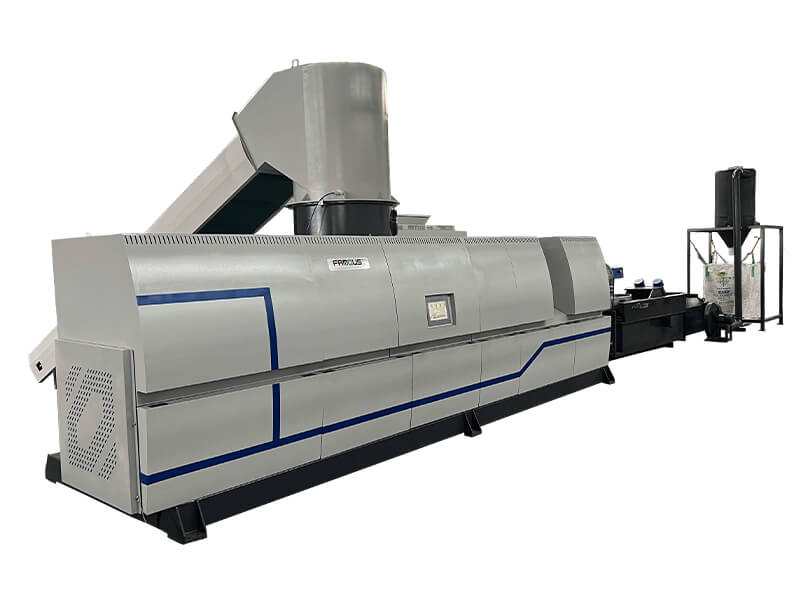

Main Machine Features And Principle

High efficiency automatic pelletizing machine from our company is designed for recycling plastic PP,PE,HDPE,LDPE, LLDPE,PA66,PC,PET,OPP,BOPET,ABS and etc. which are widely used in making bags, film rollers, stretch film, shrink film, multi-layer film, T-shirt bag cut-offs; Foamed PE, sheet, food container, fruit net, cover, fiber, raffia, silk, yarn, woven bag, jumbo bag. One pelletizing machine can produce more than 10 kinds of plastic material.

IF YOU WOULD LIKE TO KNOW MORE INFORMATION ABOUT THIS PRODUCT, PLEASE SEND US INQUIRY.

| Model | SJ85 | SJ100 | SJ130 | SJ150 | SJ180 |

|---|---|---|---|---|---|

| screw diameter(mm) | Φ85 | Φ100 | Φ130 | Φ150 | Φ180 |

| screw L/D | 20-33 | 20-33 | 20-33 | 20-33 | 20-33 |

| main motor(kw) | 22-55 | 37-90 | 45-132 | 55-185 | 75-250 |

| compactor cutter power(kw) | 37-45 | 45-55 | 75-90 | 75-110 | 90-160 |

| exhaust method | vacuum or natural exhaust | vacuum or natural exhaust | vacuum or natural exhaust | vacuum or natural exhaust | vacuum or natural exhaust |

| screen changer | plate or pillar type hydraulic screen changer | plate or pillar type hydraulic screen changer | plate or pillar type hydraulic screen changer | plate or pillar type hydraulic screen changer | plate or pillar type hydraulic screen changer |

| pelletizing type | water-ring or noodle pelletizer | water-ring or noodle pelletizer | water-ring or noodle pelletizer | water-ring or noodle pelletizer | water-ring or noodle pelletizer |

| capacity(kg/h) | 100-200 | 200-300 | 400-500 | 500-600 | 700-800 |

| Model | SJ85+SJ85 | SJ100+SJ100 | SJ130+SJ130 | SJ150+SJ150 | SJ180+SJ180 |

|---|---|---|---|---|---|

| Screw diameter(mm) | Φ85+Φ85 | Φ100+Φ100 | Φ130+Φ130 | Φ150+Φ150 | Φ180+Φ180 |

| mother extruder screw L/D | 20-33 | 20-33 | 20-33 | 20-33 | 20-33 |

| baby extruder screw L/D | 10-12 | 10-12 | 10-12 | 10-12 | 10-12 |

| mother extruder motor power(kw) | 22-55 | 37-90 | 45-132 | 55-185 | 75-250 |

| baby extruder motor power(kw) | 15-22 | 22-30 | 37-45 | 45-55 | 55-75 |

| compactor cutter power(kw) | 37-45 | 45-55 | 75-90 | 75-110 | 90-160 |

| exhaust method | vacuum or natural exhaust | vacuum or natural exhaust | vacuum or natural exhaust | vacuum or natural exhaust | vacuum or natural exhaust |

| screen changer | plate or pillar type hydraulic screen changer | plate or pillar type hydraulic screen changer | plate or pillar type hydraulic screen changer | plate or pillar type hydraulic screen changer | plate or pillar type hydraulic screen changer |

| pelletizing type | water-ring or noodle pelletizer | water-ring or noodle pelletizer | water-ring or noodle pelletizer | water-ring or noodle pelletizer | water-ring or noodle pelletizer |

| capacity(kg/h) | 100-200 | 200-300 | 400-500 | 500-600 | 700-800 |

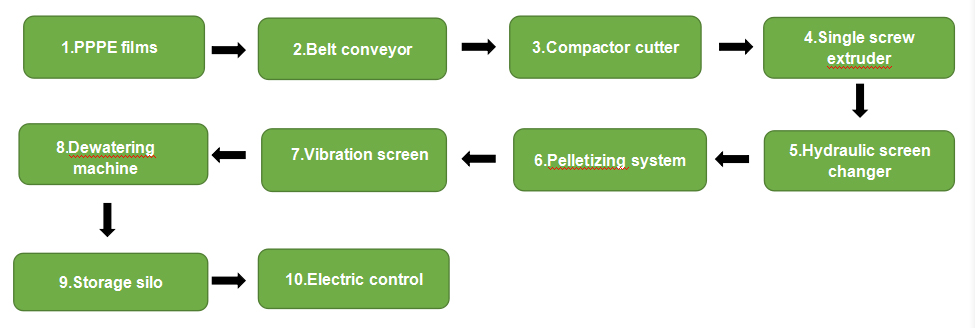

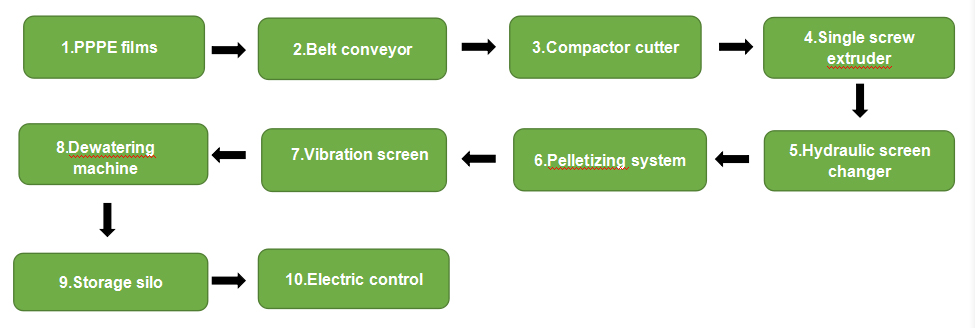

Belt Conveyor: As standard design, plastic scraps such as film, filament, raffias conveyed into the compacting room through belt conveyor; Metal detector can be combined with belt conveyor, and can interlock with control system, to warn and stop the system, in case that metal is found in feeding.

Compactor cutter/force feeder: The rotatory blades of compactor will cut up incoming scraps. Crushing, drying and compacting the material which enables a fast and stable feeding from the compactor directly into the extruder. With glass window and light to check inside working.

Extruder: A specialized single screw extruder applied to gently melt the pre-compacted material. The plastic scraps will be well melted, plasticized in a processing section. With vacuum degassing system, especially suitable to heavy printed film and material with water content.

Water-ring Die-face cutting system: Water-ring die-face/Strand cutting methods are usually adopted. In water-ring die-face cutting system, the rotary cutting blades will be pneumatically fit completely and closely to the die-face surface to ensure efficient cutting. Rotary speed of the blades is automatically adjusted by module system according to melt pressure at the die face.

Vibration drying system: Advanced dewatering vibration sieve combining with horizontal-type centrifugal dewatering present high performance dried pellets and lower energy consumption.

Dewatering Machine: Horizontal centrifugal dehydrator, after high-speed rotation, the particles will not stick to each other and be drier.

Storage silo: The big silo is used for pellets, then put into the ton bags.

The silo is covered with sound insulation cotton, to reduce the noise of materials blown into it.

Intelligent Control System: With CE standard, all parameters can be set on the touch screen.

1.Electric control component: (Siemens), e.g. Circuit-breaker, AC contact, press button,etc.

2.For electric control of the whole line.

3.All electrical units: Siemens, Schneider, ABB, Delta, Omron, RKC, etc.