Foam materials, often referred to as Styrofoam or expanded polystyrene (EPS), are ubiquitous in our daily lives. From packaging materials to disposable food containers, foam products are convenient but often criticized for their environmental impact. As awareness of plastic pollution rises, many people are asking: Is foam recyclable? In this comprehensive guide, we’ll explore the recyclability of foam, the recycling processes involved, and its broader implications for sustainability.

Foam is a lightweight material composed of numerous small air pockets. It is primarily made from polymers, particularly polystyrene, which is derived from petroleum. This versatility makes foam an ideal choice for various applications, including:

Packaging: Protective packaging for electronics and fragile items.

Food Containers: Takeout boxes, cups, and trays.

Insulation: Used in construction for thermal insulation.

Despite its practical uses, foam's environmental footprint raises significant concerns.

Foam materials are not biodegradable. Instead, they can take hundreds of years to decompose in landfills. Here are some key environmental concerns associated with foam:

Pollution: Improper disposal leads to littering, where foam breaks down into microplastics that can contaminate waterways and harm marine life.

Resource Consumption: The production of foam requires fossil fuels, contributing to greenhouse gas emissions and resource depletion.

Waste Management Challenges: Traditional recycling systems often do not accept foam due to its lightweight nature and bulkiness, leading to increased waste.

Foam recycling is possible but comes with specific limitations depending on the foam type. Most common foam products include expanded polystyrene (EPS), often used in packaging materials like Styrofoam, and polyethylene (PE) foam used for protective packaging. EPS, which is commonly identified as Styrofoam, is not widely accepted in curbside recycling programs because it is lightweight, bulky, and can be challenging to process due to its tendency to break apart into small particles. However, specialized recycling centers may accept clean EPS for repurposing into products like insulation or picture frames.

Polyethylene foam, another common type, is more recyclable, but its recyclability depends on local facilities and acceptance standards. Many recycling centers require PE foam to be free from contaminants, such as adhesives and food residue, to ensure a smooth recycling process. PE foam can sometimes be repurposed for products like park benches and new packaging materials.

When considering foam recycling, it’s essential to contact local recycling facilities to determine if they accept EPS or PE foam and understand any specific preparation guidelines they may have. Additionally, initiatives like drop-off recycling points or mail-in programs are becoming available for foam products in some regions.

In regions where recycling foam isn’t accessible, exploring reuse options can be beneficial. For instance, foam packaging can often be repurposed for future shipments or DIY projects.

while foam is recyclable under certain conditions, it requires specific processing methods and a recycling center equipped to handle the material. Check with local recycling programs or specialty centers for accurate information on recycling options, and always consider reuse as an alternative when recycling is not possible. By responsibly managing foam disposal, we can collectively reduce waste and promote sustainable practices.

Foam recycling typically involves several steps, which vary depending on the type of foam:

Foam materials must be collected separately from other waste because they decompose very slowly in landfills, causing long-term environmental impacts. Many cities do not offer curbside foam collection services, leading to challenges for consumers when disposing of these materials. Therefore, it is particularly important to know how to correctly place foam materials.

Often, consumers need to proactively seek out locally designated drop-off locations, which could be specialized recycling centers, recycling bins at malls, or community events. These measures will not only promote the recycling of materials, reduce environmental pollution, but also increase public awareness of sustainable development.

In addition, some cities regularly hold special recycling activities to encourage residents to bring foam materials for centralized recycling. This centralized method of recycling not only improves the efficiency of recycling, but also makes it easier for consumers to dispose of foam materials. Knowing this information not only helps individuals make greener choices in their daily lives, but also drives communities toward a more sustainable future.

Once the foam has been collected, sorting it is a crucial step in the recycling process. Foam materials are mainly divided into several types, including polystyrene foam (EPS), polyurethane foam and polyethylene foam. Each type of foam has different characteristics and treatment methods in the production and recycling process, so accurate classification can effectively improve the efficiency of recycling and the quality of material reuse.

For example, polystyrene foam is commonly found in takeout boxes and packaging materials, and while this foam is accepted in recycling facilities in many places, it may require special handling in some areas. Polyurethane foam is commonly used in furniture and mattresses, where the recycling process is often more complex and may require specialist equipment. Polyethylene foam, on the other hand, is often used for packaging protection and can usually be recycled directly at specific recycling points.

By sorting the foam, recycling agencies are able to more efficiently convert these materials into new products, reducing resource waste. When handling foam, consumers should be aware of local recycling guidelines to ensure that foam materials are put into the appropriate recycling channels. This will not only help the environmental cause, but also increase public awareness and participation in the proper recycling process.

Foam materials must be thoroughly cleaned before recycling to remove food debris, adhesives, and other contaminants. This step is essential to ensure the effectiveness of recycling, as contaminants not only degrade the quality of recycled materials, but can also cause recycling facilities to refuse to accept these foams.

Cleaning foam is often a labor-intensive process. Many consumers may not be aware of the importance of cleaning when dealing with foam packaging, making recycling more difficult. For commercial recycling centers, contaminated foam adds to disposal costs and can lead to entire recycling batches being scrapped. Therefore, ensuring that the foam material is as clean as possible before placing is the key to improving the success rate of recycling.

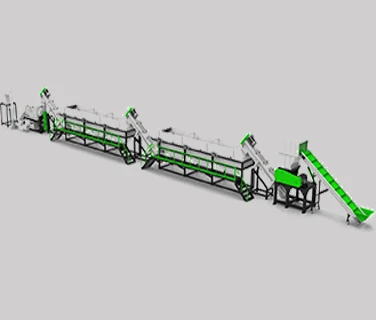

In order to reduce the time of foam cleaning and improve efficiency, the use of waste foam cleaning line is an effective solution. This dedicated device automates the cleaning process, significantly reducing labor costs and ensuring that foam meets higher cleaning standards before it is released for recycling. In addition, the use of waste foam cleaning lines can also reduce the amount of water and detergent used, as these systems are often designed to recycle resources efficiently. By optimizing the cleaning process, recycling facilities can process large volumes of foam more quickly, increasing overall recycling capacity.

Cutting the clean foam into small pieces is an integral step in the recycling process, a step that helps simplify subsequent processing and handling. By cutting the foam into smaller pieces or chunks, recycling facilities can more easily transport, store and reprocess it, improving overall efficiency.

The cut foam pieces not only take up less space and are easier to stack and dispose of, but can also be more efficiently mixed with other materials during subsequent recycling. For many reprocessing applications, standardised small block sizes can improve machining results and improve the quality of the finished product.

In addition, small pieces of foam are more easily melted, reshaped, or made into new products in melt processing or other reuse processes. These new products can be new foam materials, building insulation, or even new packaging materials, so that resources can be recycled.

In general, cutting clean foam into small pieces not only improves the efficiency of recycling and reprocessing, but also creates more possibilities for the sustainable use of foam materials, making a positive contribution to environmental protection.

After melting and processing, broken foam can be transformed into a variety of new products, fully demonstrating the recycling potential of foam materials. This process usually involves heating the clean broken foam to its melting point, transforming it into a plastic liquid state, and then forming new products through molds or other processing techniques.

Through this recycling and reprocessing process, the life cycle of the foam material is extended, effectively reducing waste generation and reducing dependence on new resources. This not only contributes to environmental protection, but also brings new growth points to the economy and promotes the development of circular economy. Overall, the reuse of foam not only makes business sense, but also contributes positively to the sustainable development goals.

Despite the potential for recycling, several challenges hinder the widespread adoption of foam recycling:

Economic Viability: The cost of collecting and processing foam often exceeds the value of the recycled material, making it less attractive for recycling facilities.

Lack of Infrastructure: Many areas lack the necessary facilities to process foam, leading to limited recycling options for consumers.

Public Awareness: Many people remain unaware of the recyclability of foam or how to properly dispose of it, leading to increased waste.

As concerns about foam waste grow, many companies and consumers are seeking alternatives. Here are some eco-friendly options:

Biodegradable Packaging: Materials made from cornstarch or other natural substances can replace traditional foam packaging.

Recycled Materials: Some companies are using recycled paper or cardboard as cushioning materials instead of foam.

Reusable Containers: Investing in durable, reusable containers can significantly reduce foam waste.

While foam presents significant environmental challenges, understanding its recyclability is the first step toward mitigating its impact. By making informed choices and advocating for better recycling practices, we can collectively reduce foam waste and promote a more sustainable future. The journey to effective foam recycling requires effort from individuals, communities, and industries alike. Together, we can create a cleaner, greener planet for future generations.