A Foam Pelletizer is a quick way to cut foam waste at work. This machine makes foam smaller, helps recycling, and lets people use the material again. Companies and buildings see fast changes in storage, moving foam, and saving new materials.

Makes big foam pieces into small pellets

Makes recycling easier

Changes waste into things you can use again

l A foam pelletizer changes big foam waste into small pellets. This makes it easier to move and recycle the foam.

l A foam pelletizer can make foam waste up to 90% smaller. This saves space and lowers the cost to move it.

l The machine does the recycling work by itself. This means people do not have to do as much work. It also makes the process faster.

l Foam pellets can be used again to make new things. This helps companies save money and use less plastic.

l Recycling foam with a pelletizer helps the environment. It puts less waste in landfills and saves resources.

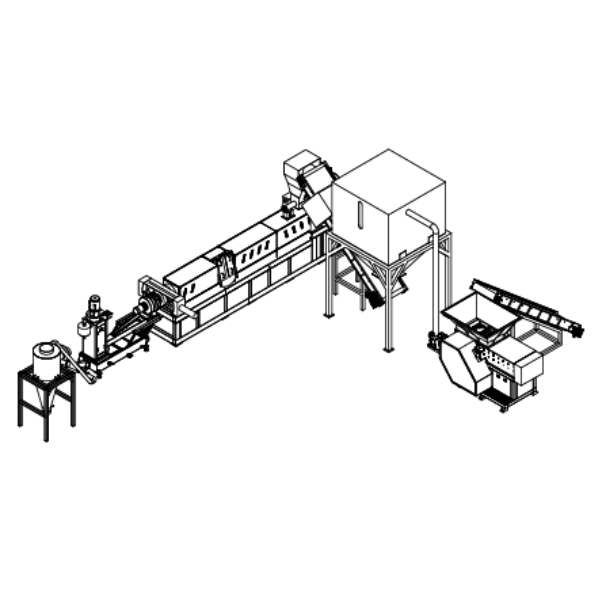

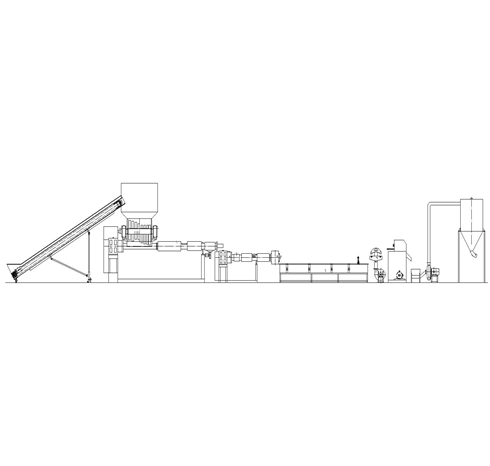

A Foam Pelletizer turns big foam waste into small pellets. Workers put large foam, like EPS, EPE, or LDPE, into the machine. First, the machine crushes the foam into tiny pieces. Then, it melts these pieces at a set heat. The melted foam goes through an extruder. This makes the foam into long, thin strands. The strands cool down in a special system. Cooling makes the foam hard again. The machine then cuts the strands into small pellets. Each pellet looks the same in size and shape. This makes foam waste much easier to handle.

Tip: Uniform pellets help companies handle waste better and get it ready for recycling or reuse.

Foam waste takes up lots of room in storage and trucks. The Foam Pelletizer can shrink foam by up to 90%. When foam turns into pellets, it fits in smaller boxes. Workers can stack and store these pellets more easily. Companies save money because they need fewer trips to move waste. Storage areas stay cleaner and more neat. Less foam means less mess at work.

l Easier to stack and store

l Cheaper to move

l Cleaner work spaces

A Foam Pelletizer helps businesses use space in a smarter way. They can do other jobs instead of worrying about big foam waste.

A foam pelletizer makes recycling foam waste much simpler. Workers do not have to sort foam by hand anymore. The machine can take different types of foam, like EPS and EPE, at the same time. This saves both time and hard work. The foam pelletizer does many jobs in one system. It crushes, melts, and shapes pellets all at once. Workers just put foam in, and the machine finishes the job.

Note: One machine can do the work of many. This helps keep the workspace neat and less crowded.

After pelletizing, moving foam waste is much easier. The small pellets are simple to pack and move. Trucks can carry more foam in each trip. This helps companies spend less on fuel and worker pay. The whole process stays easy from start to finish.

Automation is very important in recycling today. The foam pelletizer uses sensors and controls to run itself. Workers only need to watch the machine and add foam when needed. The machine does everything else. This means less hard work and fewer mistakes.

l Less sorting by hand

l Fewer workers needed

l Faster recycling

Automated machines also keep track of how much foam is processed. Companies can see the numbers right away and make smart choices. The machine can work for many hours without stopping. This lets more foam waste get recycled every day.

Tip: Automation helps companies reach recycling goals faster and with less work.

A foam pelletizer makes recycling quick and tidy. It changes a slow, messy job into a fast and easy one.

Foam pellets from a Foam Pelletizer can be used again. Many factories use these pellets to make new plastic things. The pellets melt fast and mix with other plastics. This helps companies save money on new materials.

Some things made from recycled foam pellets are:

l Picture frames

l Insulation boards

l Packing materials

l Decorative moldings

Fact: Using recycled foam pellets means less new plastic is needed. This helps save natural resources.

Factories can also sell extra pellets to other companies. This gives them more money and keeps foam waste out of landfills.

A circular economy uses things over and over. Foam pellets work well in this system. When companies recycle foam, they help close the loop. The Foam Pelletizer turns waste into something useful. This helps keep the environment clean.

Environmental benefits are:

l Less waste in landfills

l Less pollution from making new plastics

l Less energy used in making things

Tip: Companies that use recycled materials can reach green goals faster.

Reusing foam pellets helps businesses follow new waste rules. Many places now want companies to recycle more and throw away less. By using a Foam Pelletizer, companies can follow these rules and show they care about the earth.

A foam pelletizer helps companies get rid of waste quickly in three big ways:

l It makes foam waste much smaller.

l It helps recycling go faster and easier.

l It changes waste into new things people can use again.

Companies can use less space, spend less money, and help nature. Picking this machine means waste is handled fast, smart, and in a good way.

A foam pelletizer can work with many foam types. It can process EPS, EPE, and LDPE. Most machines need the foam to be clean and dry.

Companies can make foam waste much smaller, up to 90%. This means they use less space for storage and need fewer trucks. The pellets are easy to stack and keep storage tidy.

Yes, companies can sell foam pellets to factories. These pellets are used to make new things. Selling pellets helps companies make money and keeps waste out of landfills.

Most foam pelletizers have easy controls. Workers put in foam and turn on the machine. The machine does the rest by itself. Training is quick and simple.

Using a foam pelletizer keeps foam out of landfills. It also helps recycling and saves natural resources. Companies that recycle foam help protect the earth for the future.