Foam Hydraulic Compactor

Most polystyrene foam products are currently not recycled due to the lack of incentive to invest in the compactors and logistical systems required. Due to the low density of polystyrene foam, it is not economical to collect. However, if the waste material goes through an initial compaction process, the material changes density to 300 to 400 kg/m3 and becomes a recyclable commodity of high value for producers of recycled plastic pellets.

- Product Description

- Applicable Materials

- Product Features

- Specifications

PRODUCT DESCRIPTION

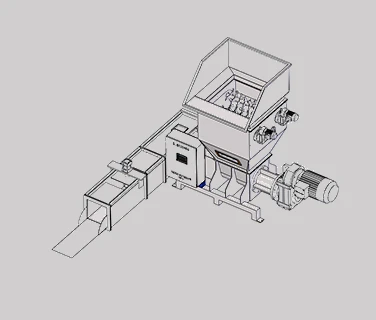

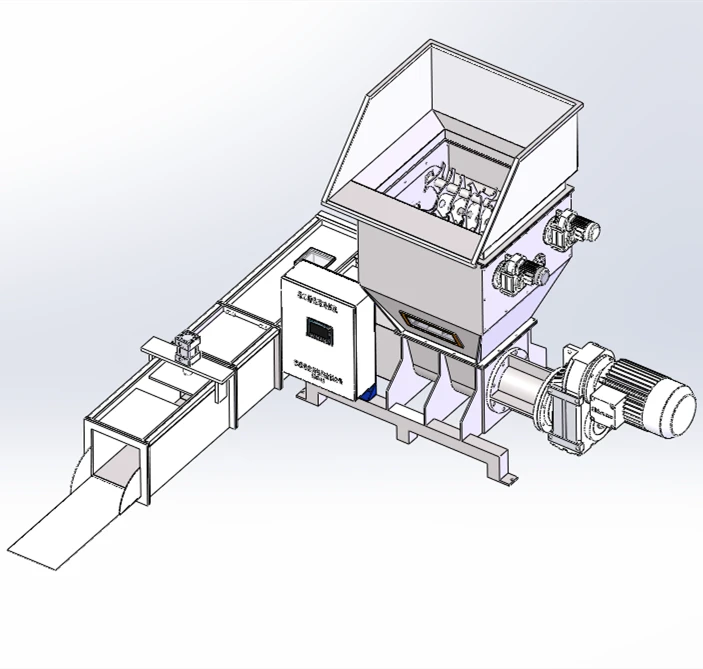

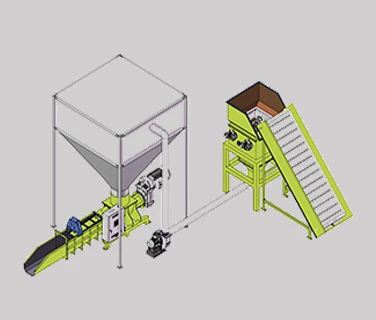

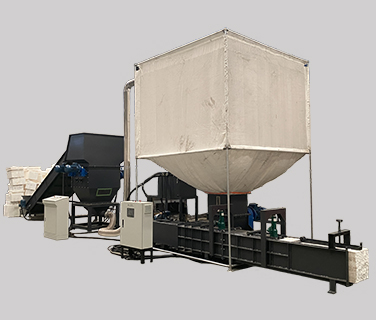

The FCP400 series is a foam hydraulic press specially used to compress waste EPS boxes, EPS dust, PU foam, EPP foam, XPS foam and other materials. Currently, Famous Machinery has launched the FCP400 large-scale foam hydraulic press based on market demand. It is made into blocks by hydraulic pressure without heating. Equipped with an efficient automatic hydraulic system, the waste EPS foam can be crushed in the storage bin of the foam hydraulic press, and then compacted into dense and uniform blocks, with a volume reduction rate of at 70:1, the volume of waste foam is greatly reduced, thereby saving storage and transportation costs.

It is worth mentioning that the FCP400 series foam hydraulic press perfectly integrates the use characteristics of foam cold press and foam hot melt machine. The foam hydraulic press not only retains the energy-saving advantages of the cold press, but also has the high-density compression effect of 90:1 of the hot melt machine, and can operate efficiently in any humid environment.

APPLICABLE MATERIALS

-

POLYSTYRENE

EPS/ EPS DUST

EPS CUPS&TRAYS/ XPS

-

POLYETHYLENE

EPE

EPE ROLL/ EPE SHEET

-

POLYPROPYLENE

EPP

PRODUCT FEATURES

Production characteristics:

1. Space saving (EPS after compaction only accounts for 2% to 5% of the original space);

2. High compression rate (density range after compaction is 300KG/m3 to 400kg/m3);

3. Compressed blocks are easy to cut and stack;

4. Stable operation and low noise;

5. The feeding port can be customized according to customer requirements, and the power/electronic control system can be replaced;

SPECIFICATIONS

Model | FCP400 |

Screw Diameter | Φ350mm |

Input size | 1000mmx900mm |

Screw rotation speed | 36rpm |

Crusher blades | about 36sets |

Blade rotation speed | 120rpm |

Main motor | 11-15kw |

Crusher motor | 3kw*4sets |

Hydraulic motor | 15-18.5kw |

Production size | 400*400mm |

Machine Weight | 3500kg |