Visit us

Sanxing Industrial Zone, Jinfeng Town, Zhangjiagang City.

Every day, people come into contact with bottles of coke and soy sauce.

The raw material of plastic bottle is pet (polyethylene terephthalate), so it is also called PET plastic bottle.

Pet was originally used as man-made fiber, negative film, magnetic tape, etc. the plastic bottle made of pet has the following characteristics:

1.Light weight, easy to handle (its weight is about 1 / 7 to 1 / 10 of the same size glass bottle);

2.Impact resistance, high strength (enough strength when dropped);

3.Use in accordance with food hygiene regulations;

4 Good transparency, luster, as a container can show a beautiful appearance;

5. Containers can be recycled and reused, which is beneficial to environmental protection (relatively speaking).

Because of its good toughness, light weight, airtight, acid and alkali resistance, Baote bottles are often used as bottled beverage packaging to hold mineral water, soda water, fruit juice, carbonated drinks, etc.

Pet has been widely used in food and beverage containers since 1976. In modern society, a large number of botte bottles are manufactured and used, but they can't be decomposed naturally, so we must recycle them after using them.

From the point of view of production process, the body and cap of PET plastic bottle are completely separated. The material of bottle body and cap is different, mainly because of the elastic coefficient. Due to the small elastic coefficient and easy deformation of pet, it is very unsafe to seal as a liquid. Therefore, HDPE is usually selected to make bottle cap and gasket for easy transportation and sales. Because of this, in Japan, Taiwan and other regions, the bottle cap, bottle body and label will be separated before recycling. In Europe, however, there is no need to separate the cap, body and label.

"Our factory has advanced automatic equipment," they explained. After entering the machine, all bottles will be cut into 1-2cm pieces. After the fragments are washed with water, the bottle body materials with different densities will be automatically layered. Then through the photoelectric screening device, they are divided into different types of regenerated fragments.

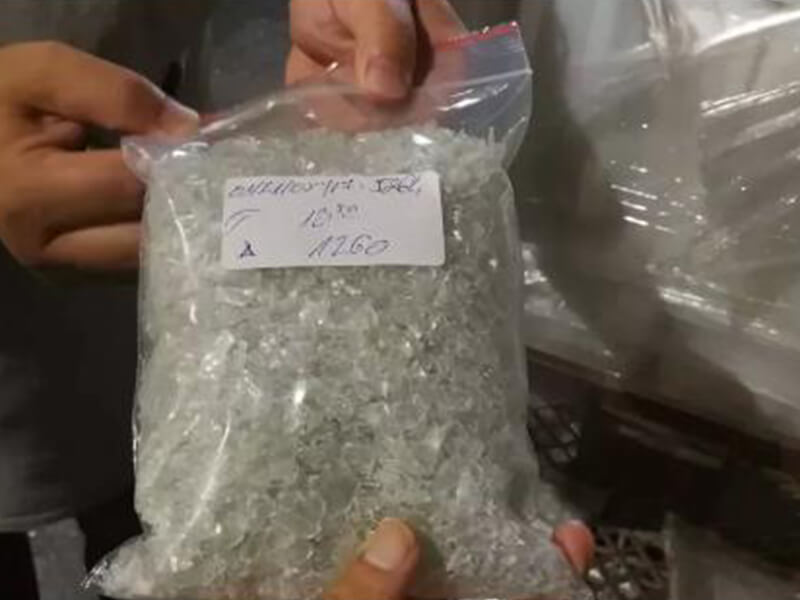

In the finished product area, we can see that the bottle body, label, cap and other materials are basically separated and rarely mixed.

PET bottle body fragment

PVC bottle body label fragment

When you don't screw the bottle cap, you don't need to tear the bottle cap. So, do we need to screw off the bottle cap and tear off the label? To find out the answer, we need to see how the downstream recycling factories around us deal with beverage bottles. This is a medium-sized beverage bottle drawing factory located around Chengdu. Most of the beverage bottles sent here didn't remove the caps and labels.

A small number of PE type plastic bottles require manual removal of caps and labels

But the general pet mineral water bottle is automatic processing

What's more, polyester fiber is directly produced from PET chips here.

Most of the PET bottle recycling plants in China are similar to this factory, with manual processing and machine processing.

Our view is that unscrewing the bottle cap and tearing the label will reduce the processing work of recyclers. I believe that recycling industry chain enterprises are also welcome. But what is more welcomed by recycling enterprises should be: we hope consumers can pour out the drinks they haven't drunk, and keep the bottles clean, dry and free of odor.