Visit us

Sanxing Industrial Zone, Jinfeng Town, Zhangjiagang City.

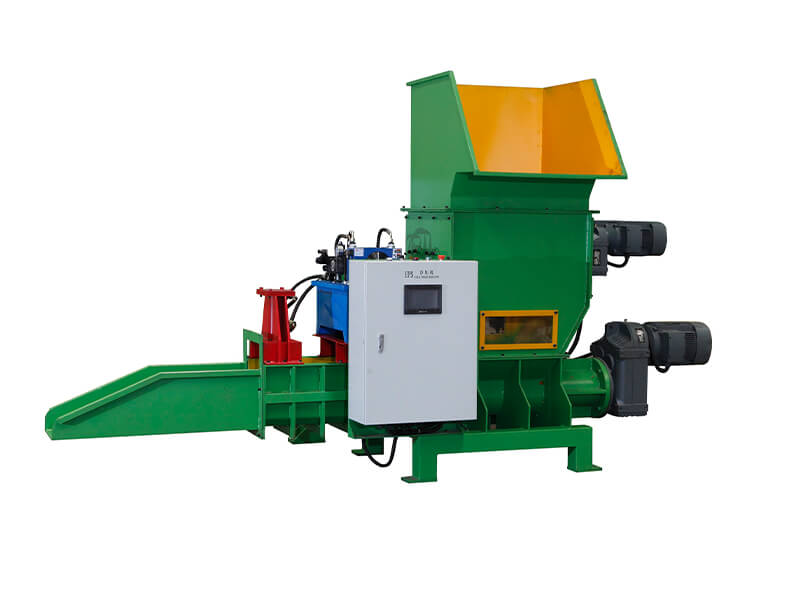

The foam recycling equipment is easy to operate, and it has won the welcome of our customers quickly. The foam waste is large, light and inconvenient to transport. Many customers need to compress the foam volume and density many times, which is conducive to the recycling of foam. A good quality eps foam recycling machine can be used for a longer time and the quality of the equipment can be seen. Its spare parts all use the world's top 500 brands, including SIEMENS, NSK, Schneider electric and so on. This effectively safeguards the life of the machine and the safety of operation. At the same time, it adopts the advanced foam compression technology in Europe and the United States and meets the national environmental standards to respond to the call of the Environmental Protection Bureau "vigorously developing renewable energy and turning waste into treasure".

Our company foam cold compactor is based on the principle of pressure generated by screw spinning to compress foamed plastics. At the same time, the latest surface hot melting technology is adopted to prevent surface melted materials, and the mechanical and environmental protection equipment for cold pressing and compressing of foam plastics can reduce foam volume and density, reduce foam volume, facilitate foam recovery and use of polyurethane foam burying. The amount of water vapor in the compressed air is determined by the temperature of the compressed air: keeping the pressure of the compressed air basically unchanged.

The more impurities contained in the foam before breaking, the more the impact will be broken. Because these impurities are easy to adhere to affect the conveying, the moisture of the foam, generally, the foam is not needed to be cleaned before crushing. As the foam itself is, it is easy to plug in the feed transportation, resulting in the decrease of crushing capacity. Therefore, the quality problem of the foam cold press machine is very important if it is only cheap, a series of legacy and maintenance cost increases will also greatly improve costs and reduce production capacity and efficiency.

As we all know, if we want our equipment to run normally for a longer time, we have to maintain it. This will not only reduce the failure rate of the equipment, but also extend the service life of the equipment.

Among them, polyfoam and phenolic foam are widely used. Regenerated foam particles have been applied in textile, automotive, food and beverage packaging, consumer electronics, etc., and some enterprises have also put forward the application demand for recycled plastics. With the release of various constraints in the future, it is easy to see that the development prospect of recycled plastics is considerable.

Due to the lack of active investment in foam compression and recovery equipment and the need of logistics system, most of the polystyrene foam waste materials are not effectively recycled at present. The main reason is that the density of polystyrene foam plastics is low.

Taking into account transportation and storage costs, it can not be well collected. If the waste material is compacted by foam compressor, the density of the foam waste can be greatly reduced to the original 1/50 and become a high-quality recyclable EPS compression block.

FAMOUS MACHINERY COMPANY foam cold presser can solve this problem very well. First, after compression, it can reduce the size of EPS foam material, the compression ratio is big, it can reach 1:50, the finished product is EPS foam plastic block, and its density can be greatly improved. It is easy to treat EPS/EPP/EPE/PSP/XPS foam board and other foam plastics into another kind of EPS compression block, for pelletizing production frame and mirror frame and other products.