Visit us

Sanxing Industrial Zone, Jinfeng Town, Zhangjiagang City.

With the rapid growth of social economy, at present we have entered the Internet era, people's consumption habits have changed dramatically, only through mobile phones can buy products from all over the country, which will inevitably lead to the rapid development of logistics industry.

Since polystyrene was invented more than 70 years ago, it has provided great convenience for people in various packaging fields. Because the quality of the foam package is light, large, and the value of direct recovery is not high, most consumers throw the foam bags directly into the dustbin, and 95% of the national foamed garbage eventually goes into landfills or is burned.

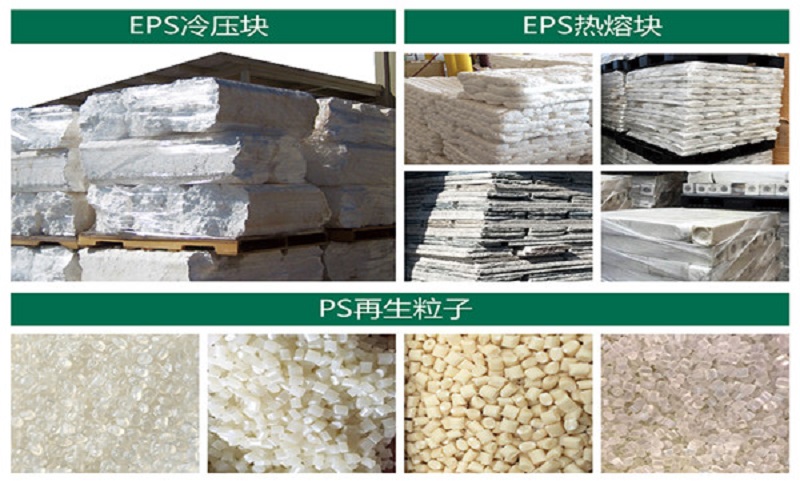

With the development of industry, the technical performance of the foam recovery equipment has been greatly improved, which provides a great guarantee for the added value of the foam waste recovery industry. The environmental friendly foam cold press is a good particle. This new type of environmental foam cold compressor is designed to crush the foam waste with a cutter. After that, the foam fragments will enter the storage tank. The screw hydraulic device will crush the broken foam waste into blocks as needed to recycle the granulation. With this low energy consumption and remarkable energy saving effect, the compression ratio of foam waste can be reduced to 50 of the original, and the transportation cost can be greatly saved.

Only the high density polystyrene foam waste compression block can be used for granulation to produce many other products, such as frames, photo frames, etc.