Visit us

Sanxing Industrial Zone, Jinfeng Town, Zhangjiagang City.

Are you looking for top-notch plastic recycling machine to process different kind of waste materials? Look no further! Our company is proud to offer an extensive range of high-quality and professional plastic machinery, including plastic shredders, plastic crushers, plastic pelletizers, plastic washing lines, eps foam melting machines, eps foam compactor machines, and eps foam pelletizers. Our products have gained a reputation for their outstanding performance and reliability.

Our shredders are designed to efficiently and effectively shred plastic materials into smaller sizes. Equipped with robust blades and advanced control systems, They can handle various types of wastes, including PE, PP, PS, PVC, ABS, PC, PET, EPS, Wood, etc. making them versatile for a wide range of recycling applications.

Our crushers are engineered to crush different types of waste plastics (films, bags, bottles, pipes, profiles, sheets, plates, boards, barrels, buckets, containers, foams, etc.) into flake forms, facilitating further processing. With their innovative design and powerful motors, our crushers ensure precise and consistent results. Additionally, they have a user-friendly interface, allowing operators to easily adjust parameters for optimized performance.

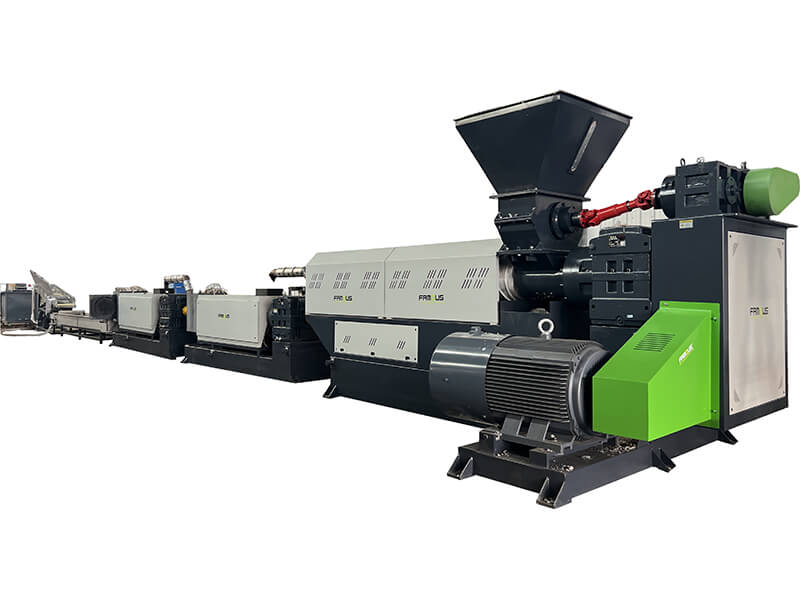

Our pelletizers can make plastic materials (pp pe films, bags, bottle flakes, sheets, etc.) into uniform-sized pellets. We offer high efficiency and low energy consumption. They can rapidly extrude plastic pellets, ensuring a consistent product quality that meets the industry's standards.

The whole pelletizing line has a high degree of automation. In order to be a fully automatic production line, only one person needs to feed to the conveyor belt to realize the direct transformation from waste plastics to granule products.

On the basis of advanced technology at home and abroad, the whole production line is continuously improved and improved, with reasonable design, beautiful appearance, durable, and stainless steel is used in the contact parts with materials.

The finished product has high quality, no bubbles, full and round, beautiful appearance, round shape, size and thickness can be adjusted.

The forcible feeding device, main machine and granulator of granulation mitochondria can be controlled by frequency converter or programmable remote control.

The granulator screw and barrel are made of 38CrMoAl material. The surface is nitrided and hardened, and the service life is very long.

The granulator is directly cut by water ring pelletizer or spaghetti pelletizer on the die head. Horizontal or vertical water ring can be used. After water cooling, the granulator enters the centrifugal dehydrator, and then is sent to the storage silo by the blower.

There are drains and vacuum pumps on the barrel of granulator to drain and exhaust to ensure the quality of particles.

Hydraulic screen changer without stopping granulation machine. Pressure sensor on the die tip prompts net-changing. The net-changing does not need to stop. The net-changing speed is fast and convenient.

Our washing lines are specifically designed for thoroughly cleaning and recycling plastic materials (pp pe films, bags, bottles, sheets, barrels, etc.). Equipped with advanced crushing washing drying systems, our washing lines remove impurities and contaminants, resulting in clean, high-quality plastic flakes. Furthermore, our washing lines are highly customizable to suit different types of plastics and specific processing requirements.

Our hot melt machines are engineered to crush and melt expanded polystyrene (EPS/EPE/EPP/XPS/LDPE/PS) foam waste into dense and compact blocks. By utilizing high temperatures and pressure, our machines ensure efficient foam waste reduction while preserving the material's properties. The resulting blocks can be easily transported and recycled into new EPS products.

Our cold press machines are designed to compress and densify foam waste (EPS/EPE/EPP/XPS/LDPE/PS) into manageable blocks. With their precise control systems and compact designs, our cold press machines offer exceptional compression ratios, reducing the volume of foam waste significantly. These blocks can be conveniently stored and transported for further recycling.

This eps pelletizer for foam waste are specifically developed to transform compressed foam blocks into uniform-sized pellets. Equipped with advanced pelletizing system and automatic control, our pelletizers ensure high precision and efficiency. The resulting eps pellets can be reused in various industries, reducing waste and promoting sustainability.

In conclusion, our company offers a comprehensive range of professional plastic machinery that mainly in shredding, crushing, pelletizing, washing, melting, compacting, etc. With their superior performance and excellent after-sales team, Our products have made a contribution to the development of the plastic recycling industry. Trust our expertise and choose our machinery to optimize your plastic recycling processes and have a positive impact on reducing environmental pollution.