Main features:

1. Compacting expanded polystyrene with a density of 350-400kg/m3

2. Save costs for transport and land fill

3. Save space and handling by dealing with the EPS in a quick and efficient manner

4. Generate income from sales of the compacted EPS blocks, save power consumption

5. No heat is added to the process

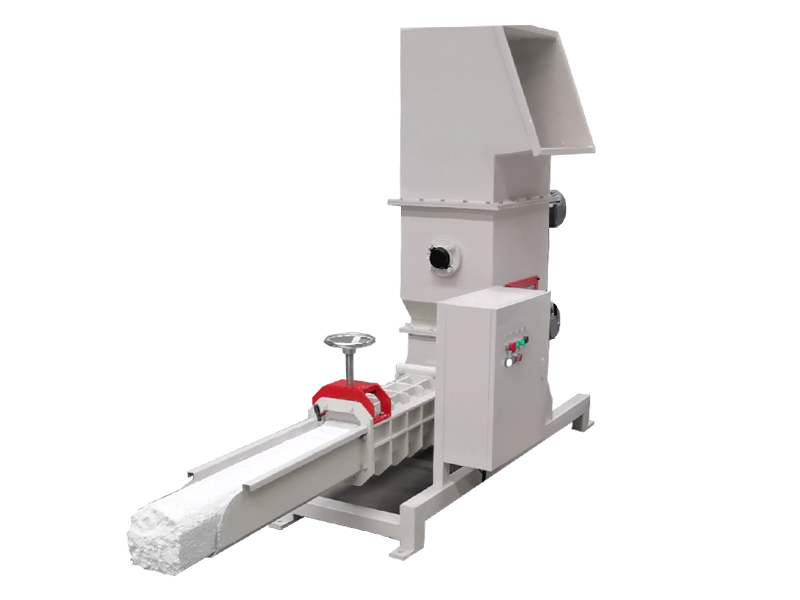

EPS cold compactor is specially used for EPS plastic foam and polystyrene foam, such as foam box, EPS foam board, EPS foam fast food box, etc.

Product applications:

The large foam compactor is used to compress the capacity of EPS foam plastics, increase the density, compress the EPS foam into lumps, greatly reduce the volume of EPS foam, facilitate the recovery, stacking, storage and transportation of foam plastics, save space and reduce transportation costs, and increase economic benefits.

Working principle:

Put the polystyrene foams into the crushing bin, and the motor drives the crushing room to break the foams(Polystyrene foam box) into small pieces. The foams that pass will be screened through the filter screen. Those that pass will enter the squeezing part, while those that don't will continue to break until they pass. The extrusion is fed by motor driven screw. There is a water tank between the discharge channel and the extrusion part. Two water pipes are connected on the water tank for water circulation and cooling effect. When the screw transfers small pieces of foam to the front of the outlet, the surface of the outlet is covered with a layer of 304 stainless steel, and the upper part is pressed by a hydraulic pump, so it is difficult to extrude the foam during the discharge. Wait for the foam block to be pushed out by the screw. When the hydraulic pump drops down and there is no material, the cover plate and the upper surface of the discharge channel can form a negative Angle and wait for the accumulation of foam blocks, and then repeat the previous action in a cycle.